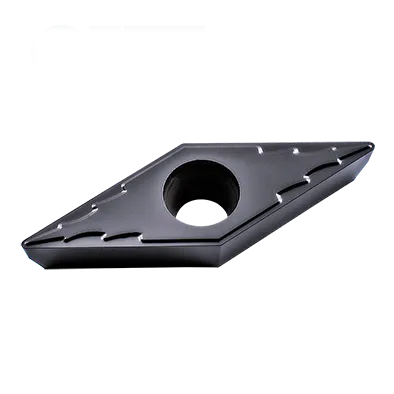

VCMT insert

VCMT insert angle:35 degrees 7° Positive Rake Insert with single-sided Chipbreaker;

Screw-On Insert, Finishing machining;

VCMT insert sizes: IE6.35mm/9.525mm;LE11mm/16.5mm;RE0.4mm/0.8mm/1.2mm;

Matching VCMT insert Tool Holder: SVJBR/L, SVABR/L, SVVBN, SVQBR/L, SVUBR/L;

Range of VCMT insert types:(ISO)VCMT1103/ VCGT1604;

VCMT Insert can deal with multiple operations by combining different chip breakers and grades;

產品介紹

The insert is mainly used for semi-finishing or finishing applications.

The diamond shape with a 35 degree top angle has the widest accessibility and provides the best surface finish when machining out of round.

With our proprietary coating, the insert is suitable for most materials.

主要特點

- 形狀: VCMT inserts feature a 35° rhombic (diamond) shape, giving them four cutting edges for cost-effectiveness. This narrower angle enhances strength at the cutting tip.

- 正前角: The cutting face slopes slightly forward from the cutting edge. This often produces a smoother cut with lower cutting forces, suitable for softer materials or low-power machines.

- 間隙角: Typically 7° to help prevent rubbing against the workpiece.

- 斷屑槽: VCMT inserts feature various chipbreaker geometries to control chip formation and flow.

- 塗料: Often coated with materials like TiN, AlTiN, etc., to improve wear resistance and tool life.

VCMT insert Specification

Understanding the Insert Code

V: Shape. Rhombic (diamond) with a 80-degree included angle.

C: Clearance Angle. 7 degrees (positive).

M: Tolerance. Typically medium tolerance, but other options might be available.

T: Chipbreaker style & Hole Configuration. This letter identifies the specific chipbreaker geometry and hole presence/absence. Chipbreaker variations are numerous and manufacturer-specific.

數字:

First Two Digits: Inscribed circle (IC) diameter in millimeters. To obtain the approximate inch equivalent, divide this number by 25.4.

Next Two Digits: Thickness in millimeters. Divide by 25.4 to convert to inches.

Last Two Digits: Nose radius in millimeters. To convert to inches, divide by 25.4.

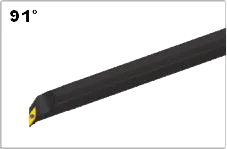

VCMT insert holder(Boring bar)

SVQBR/L

SVUBR/L

Carbide VCMT Insert Dimensions (ISO)

| 指定 | 內切圓 (IC) | 厚度 | 轉角半徑 |

|---|---|---|---|

| VCMT 110302 | 11mm (0.43") | 3.18mm (0.125") | 0.2mm (0.008") |

| VCMT 110304 | 11mm (0.43") | 3.18mm (0.125") | 0.4mm (0.016") |

| VCMT 160404 | 16mm (0.63") | 4.76mm (0.187") | 0.4mm (0.016") |

| VCMT 160408 | 16mm (0.63") | 4.76mm (0.187") | 0.8mm (0.031") |

Example: VCMT 160408 (ISO)

- Rhombic (diamond) shape with an 80-degree included angle

- 7 度正間隙角

- 中等耐受性

- 製造商特定的斷屑槽和孔配置

- 16mm 內切圓直徑(約 0.63″ 以英吋為單位)

- 4mm thick (approx. 0.157″ 以英吋為單位)

- 0.8mm 刀尖半徑(約 0.031″ 以英吋為單位)

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

硬質合金刀片是目前最通用、最耐用的切削工具之一。但它們是如何製作的呢?是什麼讓他們如此強大?在本影片中,我們將探索硬質合金刀片背後的科學,從碳化鎢的特性到製造流程。

我們的生產能力

在現代製造業中,高性能硬質合金刀片是不可或缺的工具,為高效、精確的金屬加工奠定了基礎。然而,這些特殊的插入物並不是自行存在的。他們得到了先進機械的堅定支持。