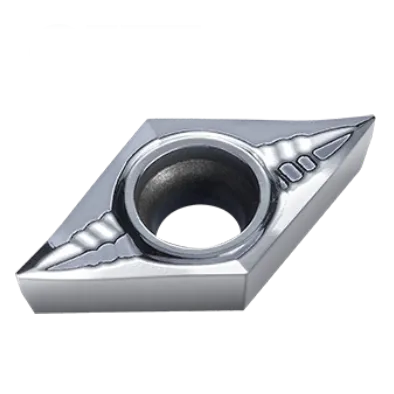

DCGX車刀

DCGX insert angle:7° Positive rake insert with a single-sided chipbreaker;

55°菱形車削刀片;

主要工件材料:鋁;

斷路器應用:半綁架和整理加工;

匹配的轉彎工具支架:SDQCR/L,SDUCR/L;

材質:碳化鎢;

DCGX insert specification

G class tolerance with big rake angle, polish and ground on surface, special geometry is resistant to chip built-up on the insert edge, maximize surface finish on aluminum machining and insert tool life.

DCGX insert tool holder

DCGX insert Introduction

Understanding the DCGX Insert Code

- d: 形狀:菱形(菱形),夾角為 55 度。

- C: Clearance Angle: 7 degrees (positive).

- 克: 寬容: “G” indicates a medium tolerance range, though other precision tolerances may exist.

- X: 斷屑槽樣式 & 孔配置。該字母表示特定的斷屑槽幾何形狀以及刀片是否有孔。斷屑槽種類繁多,且因製造商而異。

- 數字:

- 前兩位數字: 內切圓 (IC) 直徑(以毫米為單位)。要獲得近似的英吋當量,請將此數字除以 25.4。

- 接下來的兩位數字: 厚度以毫米為單位。除以 25.4 即可轉換為英吋。

- 最後兩位數字: 鼻尖半徑(以毫米為單位)。要轉換為英寸,請除以 25.4。

- 數字:

DCGX Insert Dimensions (ISO)

| ISO 名稱 | 內切圓 (IC) | 厚度 | 轉角半徑 |

|---|---|---|---|

| DCGX 070202 | 7.94mm (0.313") | 2.38mm (0.094") | 0.2mm (0.008") |

| DCGX 070204 | 7.94mm (0.313") | 2.38mm (0.094") | 0.4mm (0.016") |

| DCGX 11T302 | 11mm (0.433") | 3.18mm (0.125") | 0.2mm (0.008") |

| DCGX 11T304 | 11mm (0.433") | 3.18mm (0.125") | 0.4mm (0.016") |

| DCGX 11T308 | 11mm (0.433") | 3.18mm (0.125") | 0.8mm (0.031") |

Example: DCGX 11T308

- Rhombic (diamond) shape with a 55-degree included angle.

- 7-degree positive clearance angle.

- 中等耐受性。

- 製造商特定的斷屑槽和孔配置。

- 11mm 內切圓直徑(約 0.43″ 以英吋為單位)。

- 3.18毫米厚(約0.125″ 以英吋為單位)。

- 0.8mm 刀尖半徑(約 0.031″ 以英吋為單位)。

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

硬質合金刀片是目前最通用、最耐用的切削工具之一。但它們是如何製作的呢?是什麼讓他們如此強大?在本影片中,我們將探索硬質合金刀片背後的科學,從碳化鎢的特性到製造流程。

我們的生產能力