3刃立銑刀

A 3 flute end mill is a versatile cutting tool with three helical grooves designed for efficient chip removal, coolant flow, and structural integrity. It offers a balance between material removal rate and surface finish, making it suitable for a wide range of materials including soft materials like aluminum and copper alloys, as well as harder steels and other metals. Common applications include profiling, slotting, and pocketing.

3 flute end mill Application

- Non-ferrous materials: Aluminum, copper, and brass are commonly machined using 3 flute end mills due to their ability to handle higher feed rates and produce good surface finishes.

- General milling: Profiling, slotting, and pocketing are common operations performed with 3 flute end mills.

- Medium material removal rates: While not as aggressive as 2 flute end mills, they offer a balance between chip removal and surface finish.

- Grooving: The three flutes can effectively handle chip loading in grooving operations.

- Chamfering and deburring: Some 3 flute end mills are designed specifically for these applications.

3 flute end mill Features

- Three helical flutes: These evenly spaced flutes efficiently remove chips, improve coolant flow, and enhance tool strength.

- Balanced chip load: The three flutes distribute cutting forces evenly, reducing vibration and improving tool life.

- Good surface finish: The flute geometry typically produces a smooth finish on the workpiece.

- 多功能性: Suitable for a wide range of materials and machining operations.

- Moderate material removal rate: Provides a balance between aggressive cutting and tool life.

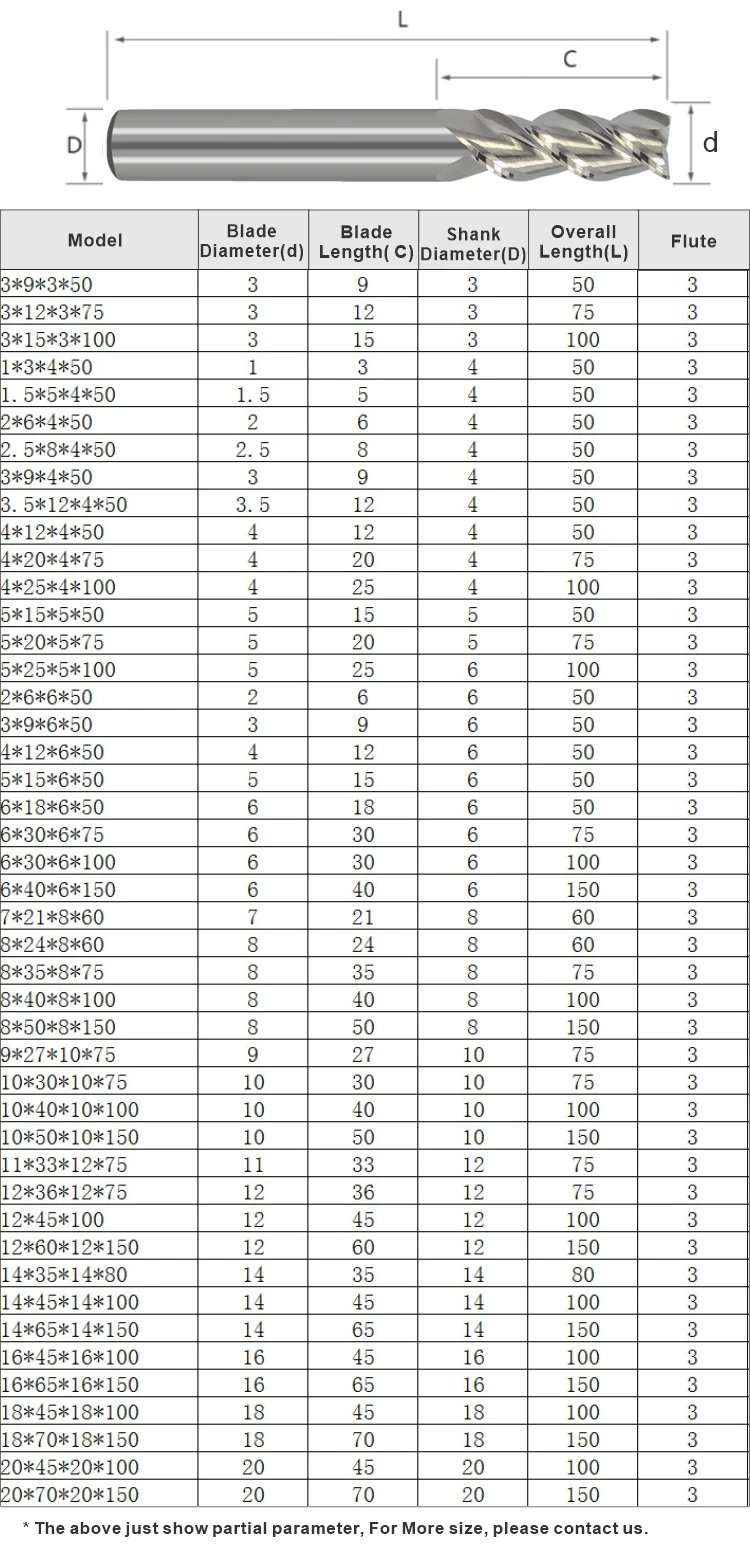

- Available geometries: Various flute lengths, helix angles, and diameters to match specific applications.

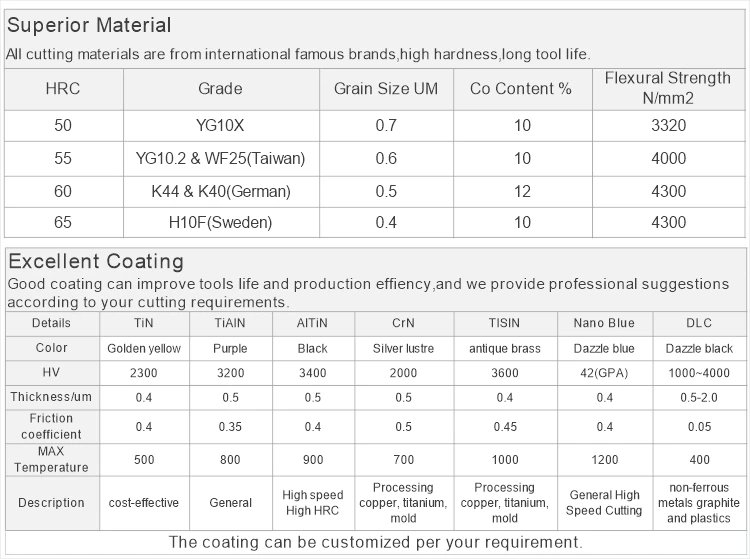

- Coating options: Often coated with materials like TiN or TiAlN to improve wear resistance and performance.

Edge passivation

3 flute end mills feature three evenly spaced helical flutes that efficiently evacuate chips, enhancing tool life and surface finish. By distributing cutting forces evenly, they reduce vibration and improve overall performance. The flute geometry of a 3 flute end mill is designed to smooth the cutting edge, increasing the surface quality of the machined part while extending tool life.

Spiral design

A 3 flute end mill boasts sharp cutting edges, facilitating efficient material removal. Its large chip removal grooves effectively evacuate chips, preventing clogging and tool breakage. The non-stick coating minimizes friction and heat generation, enhancing tool life and surface finish. These attributes make it a versatile choice for a wide range of machining applications.

Round handle chamfer

A 3 flute end mill often features a universal chamfer on its shank, facilitating quick and secure tool installation. This design prevents slipping during clamping, ensuring optimal performance and operator safety. The chamfered shank also aids in chip evacuation, reducing the risk of tool breakage.

ONMY TOOLINGS 的差異

是什麼讓我們的單槽立銑刀與眾不同?這是我們獨特的組合:

先進的硬質合金配方

我們使用針對強度和耐磨性進行最佳化的專有微晶碳化物混合物。

創新的幾何形狀

我們專利的槽設計可最大限度地排屑並最大限度地減少切削力。

尖端塗料

我們採用奈米層狀 PVD 塗層來增強耐熱性並減少摩擦。

精密研磨

我們的多軸 CNC 磨床的公差可達 ±0.0005 英吋。

Don't just take our word for it. Here's what our satisfied customers have to say:

我快樂的客戶!

立即取得您的客製報價!

附:我們是否提到我們提供批量折扣?訂購越多,節省越多!

- 無與倫比的工廠直銷定價:省去中間商,與零售價相比可節省高達 40%。我們高效的製造流程使我們能夠以具有競爭力的價格提供優質的產品。

- 閃電般的快速交付:憑藉我們簡化的生產流程,我們提供業界領先的周轉時間。只需 7 天即可獲得客製化立銑刀!我們擁有大量標準尺寸庫存,可立即出貨。

- 個人化服務:我們的專家工程師團隊隨時準備協助您找到應對獨特加工挑戰的完美解決方案。我們提供免費諮詢來分析您的特定需求並推薦理想的工具規格。

經常問的問題

- For roughing operations in softer materials: A 3 flute end mill might be a good choice.

- For finishing operations or harder materials: A 4 flute end mill is often preferred

Three Flute End Mills feature the same flute spacing as two-flute tools but offer enhanced strength. They are versatile, suitable for both ferrous and non-ferrous materials. Four Flute End Mills provide superior strength, enabling higher feed rates compared to three-flute options. However, their flute spacing is narrower, resulting in smaller chips.

Generally, a 2 flute end mill is preferred for machining aluminum.

- Larger chip load: Two flutes create larger chip spaces, allowing for better chip evacuation, especially important in soft materials like aluminum where chip loads can be high.

- Higher material removal rates: The larger chip load enables faster cutting speeds and higher feed rates.

- Reduced cutting forces: Fewer flutes can lead to reduced cutting forces, which is beneficial for aluminum machining.

While 3 flute end mills can be used for aluminum, they tend to be better suited for harder materials or when a finer finish is required.

While 2 flute end mills are typically preferred for aluminum due to their superior chip removal capabilities, 3 flute end mills offer more versatility and can be a good choice for various applications. Ultimately, the best choice depends on specific machining conditions and desired results.

A 3 flute ball nose end mill is primarily used for contouring, profiling, and finishing operations on curved surfaces. Its rounded tip allows for smooth transitions between different radii, making it ideal for creating complex shapes.

The three flutes contribute to balanced chip load, good surface finish, and overall tool performance. By selecting the appropriate carbide grade and geometry, 3 flute carbide end mills can be optimized for specific machining conditions.

A 3 flute roughing end mill is primarily used for removing large amounts of material quickly and efficiently. While not as aggressive as a 2 flute roughing end mill, it offers a balance between material removal and tool life.

Key applications include:

- Rapid material removal: Clearing away excess material before finishing operations.

- Semi-finishing: Achieving a smoother surface than roughing but before final finishing.

- General milling: Suitable for various roughing tasks in a wide range of materials.