extruded tungsten carbide strips

Extruded tungsten carbide strips are a specific type of tungsten carbide bar made using the extrusion manufacturing process. This process allows for the creation of very long, continuous strips with a uniform cross-section.

The Extrusion Process

Think of it like squeezing toothpaste from a tube or making pasta.

- Mixing: Tungsten carbide powder and a binder (typically cobalt) are mixed with a plasticizer or polymer. This turns the dry powder into a thick, paste-like or clay-like substance.

- Extruding: This paste is then forced under high pressure through a die—a hardened tool with a precisely shaped opening (in this case, a rectangle). This forms a long, continuous “green” (unsintered) strip.

- Cutting & Sintering: The long green strip is cut to the desired lengths. It then goes through a heating process (sintering) that removes the plasticizer and fuses the tungsten carbide and cobalt particles together, resulting in an extremely dense and hard final product.

Key Advantages of Extrusion

The primary benefit of extrusion over standard die pressing is the ability to create parts with a consistent profile over very long lengths.

- Longer Lengths: Extrusion can produce strips that are much longer than what is feasible with traditional pressing, which is limited by the size of the press mold. This is ideal for applications needing a long, seamless wear surface or cutting edge.

- Uniform Density: The process promotes a very uniform and consistent density and grain structure along the entire length of the strip.

- Complex Shapes: While this query is about strips, the extrusion process is also excellent for creating rods, tubes, and other complex custom profiles that are difficult to mold.

The final material properties, such as hardness and wear resistance, are determined by the specific grade (carbide/cobalt ratio) and are comparable to those of strips made by other methods. The main difference lies in the shape and length capabilities offered by the manufacturing process.

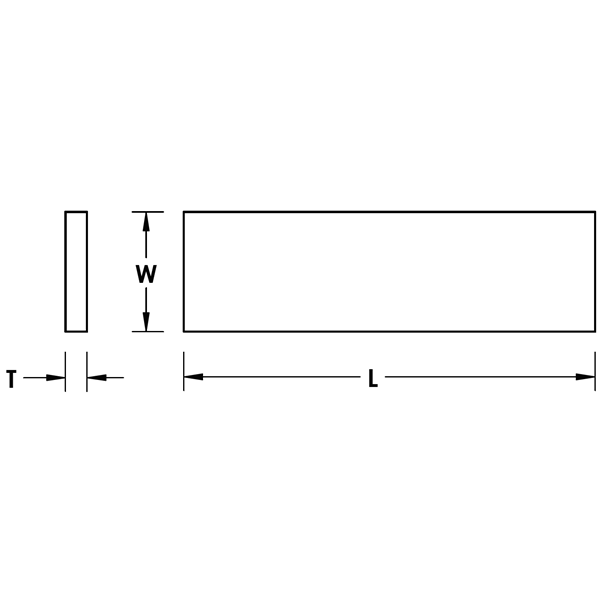

| T(Thickness) | W(Width) | L(Length) | ||

|---|---|---|---|---|

| Finished(mm) | Tolerance(mm) | Finished(mm) | Tolerance(mm) | (mm) |

| 2 | +0.3/-0.1 | 3 | +0.4/+0.2 | 310 |

| 2 | +0.3/-0.1 | 4 | +0.4/+0.2 | 310 |

| 2 | +0.3/-0.1 | 5 | 10.1/10.2 | 310 |

| 2 | +0.3/-0.1 | 6 | +0.4/+0.2 | 310 |

| 2 | +0.3/-0.1 | 8 | +0.4/+0.2 | 310 |

| 2 | +0.3/-0.1 | 10 | +0.4/+0.2 | 310 |

| 2 | +0.3/-0.1 | 12 | +0.4/+0.2 | 310 |

| 2 | +0.3/-0.1 | 14 | +0.4/+0.2 | 310 |

| 2 | +0.3/-0.1 | 15 | +0.4/+0.2 | 310 |

| 2 | +0.3/-0.1 | 16 | +0.4/+0.2 | 310 |

| 2 | +0.3/-0.1 | 18 | +0.4/+0.2 | 310 |

| 2 | +0.3/-0.1 | 19 | +0.4/+0.2 | 310 |

| 3 | +0.3/-0.1 | 3 | +0.4/+0.2 | 310 |

| 3 | +0.3/-0.1 | 4 | +0.4/+0.2 | 310 |

| 3 | +0.3/-0.1 | 5 | +0.4/+0.2 | 310 |

| 3 | +0.3/-0.1 | 6 | +0.4/+0.2 | 310 |

| 3 | +0.3/-0.1 | 8 | +0.4/+0.2 | 310 |

| 3 | +0.3/-0.1 | 9 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 10 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 11 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 12 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 13 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 15 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 16 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 18 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 20 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 22 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 25 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 28 | +0.6/+0.2 | 310 |

| 3 | +0.3/-0.1 | 31 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 5 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 6 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 8 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 10 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 12 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 13 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 15 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 16 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 18 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 20 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 22 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 25 | +0.6/+0.2 | 310 |

| 4 | +0.3/-0.1 | 30 | +0.6/+0.2 | 310 |