LNMU داخل کریں۔

Are inconsistent milling results or high tooling costs hindering your production efficiency? LNMU milling inserts are the innovative solution trusted by industry leaders worldwide. These high-performance inserts are engineered to elevate your milling capabilities, tackling your most challenging machining tasks with ease.

Why LNMU Milling Inserts Are Reshaping the Metalworking Industry

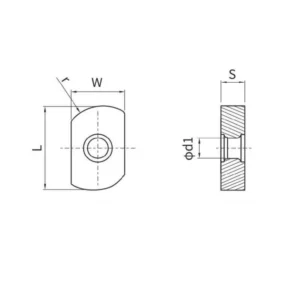

- Versatile rhombic geometry for enhanced stability and cutting performance

- Advanced chip-breaker technology for superior chip evacuation in milling operations

- Engineered for high-speed and heavy-duty milling applications

- Exceptional edge strength for extended tool life in various milling processes

The LNMU Milling Insert Advantage: Elevating Your Machining Performance

- Reduce milling time by up to 30%

- Decrease tooling costs with longer-lasting inserts

- Achieve consistent, high-quality surface finishes across diverse milling operations

- Minimize downtime with quick and easy indexing

- Increase overall productivity and profit margins in your milling processes

Selecting the Ideal LNMU Milling Insert for Your Application

- Reduce milling time by up to 30%

- Decrease tooling costs with longer-lasting inserts

- Achieve consistent, high-quality surface finishes across diverse milling operations

- Minimize downtime with quick and easy indexing

- Increase overall productivity and profit margins in your milling processes

Frequently Asked Questions

LNMU is an ISO designation where ‘L’ indicates a rhombic 80° shape, ‘N’ denotes the relief angle, ‘M’ signifies medium tolerance, and ‘U’ represents a specific chip breaker design optimized for milling applications.

- Excellent stability during various milling operations

- Versatility across different materials and cutting conditions

- Superior chip control and surface finish in milling processes

- High cutting edge strength for demanding milling applications

- Suitability for both roughing and finishing in milling operations

LNMU inserts offer a balance of strength and versatility in milling applications. Their rhombic shape provides stability for various milling operations, while the ‘U’ chip breaker design offers improved chip control compared to some other insert types, especially in challenging milling scenarios.

Our Production Capability