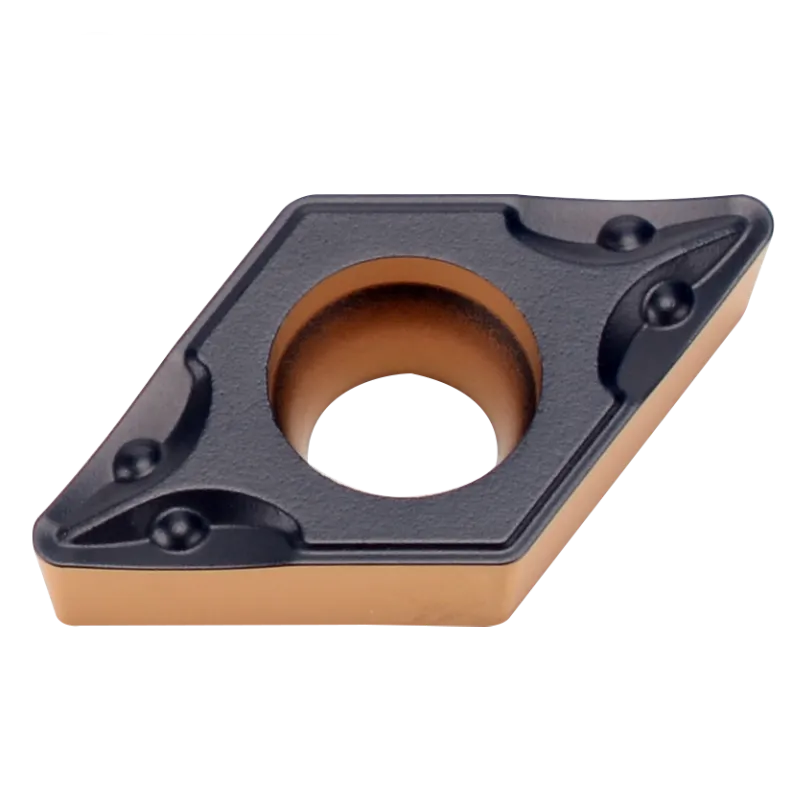

DCMT ڈالیں۔

DCMT insert angle: 7° Positive rake insert with a single-sided Chipbreaker;

55° rhombic turning insert;

Recommended for steel, stainless steel, and cast iron;

Breaker Application: Semi-finishing machining;

Matching DCMT insert holder: SDQCR/L, SDUCR/L;

Material : Tungsten carbide;

Grade: Both PVD and CVD;

Application industry: Die & mould, medical devices, manufacturing, and others;

DCMT insert specification

DCMT insert meaning a diamond-shaped (55 degrees), indexable cutting insert with a 7-degree clearance angle, moderate tolerances, and a built-in chipbreaker.

These inserts are commonly used for various turning operations in metalworking.

The nose radius has crucial effects on the surface finish, chip breaking, and insert strength.

We offer several different nose radius selections to help to enhance working quality. Generally speaking, Small nose radius will lead to small cutting depth, reduce vibration and enhance chip breaking.

On the other side, the large nose radius will be suitable for high feed rate, large depths of cut, and strong edge stability.

The relationship between nose radius and depth of cut affects vibration tendencies.

DCMT insert tool holder

DCMT insert Meaning

Understanding the DCMT Insert Code

- d: Shape: Rhombic (diamond) with a 55-degree included angle.

- C: Clearance Angle: 7 degrees (positive)

- M: Tolerance: Medium tolerance is standard, though other precision tolerances might be available.

- T: Chipbreaker style & Hole Configuration. This letter designates the specific chipbreaker geometry and whether the insert has a hole or not. Chipbreaker variations are numerous and manufacturer-specific.

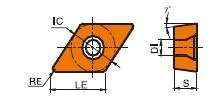

- Numerical Digits:

- First Two Digits: Inscribed circle (IC) diameter in millimeters. To obtain the approximate inch equivalent, divide this number by 25.4.

- Next Two Digits: Thickness in millimeters. Divide by 25.4 to convert to inches.

- Last Two Digits: Nose radius in millimeters. To convert to inches, divide by 25.4.

DCMT Insert Dimensions (ISO and ANSI)

| DCMT Insert Sizes | |||

|---|---|---|---|

| DCMT Designation | Inscribed Circle (IC) | موٹائی | Common Corner Radii |

| DCMT 21.51 (DCMT 0702) | 0.25" (1/4") | 0.094" (3/32") | 0.0156" (1/64") |

| DCMT 070204 | 7.94mm (0.313") | 2.38mm (0.094") | 0.4mm (0.016") |

| DCMT 32.51 (DCMT 11T3) | 0.5" (1/2") | 0.156" (5/32") | 0.0312" (1/32"), 0.0469" (3/64"), 0.0625" (1/16") |

| DCMT 11T304 | 11mm (0.433") | 3.18mm (0.125") | 0.4mm (0.016") |

| DCMT 11T308 | 11mm (0.433") | 3.18mm (0.125") | 0.8mm (0.031") |

Example: DCMT 11T308

- Rhombic (diamond) shape with a 55-degree included angle

- 7-degree positive clearance angle

- Medium tolerance

- Manufacturer-specific chipbreaker and hole configuration

- 11mm inscribed circle diameter (approx. 0.43″ in inches)

- 3.18mm thick (approx. 0.125″ in inches)

- 0.8mm nose radius (approx. 0.031″ in inches)

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Carbide inserts are some of the most versatile and durable cutting tools available. But how are they made? And what makes them so strong? In this video, we’ll explore the science behind carbide inserts, from the properties of tungsten carbide to the manufacturing process.

Our Production Capability