پریمیم کاربائڈ اینڈ مل سپلائر

آج کے مسابقتی مینوفیکچرنگ لینڈ اسکیپ میں ، ایک قابل اعتماد کاربائڈ اینڈ مل سپلائر کے ساتھ شراکت میں صحت سے متعلق ، کارکردگی اور لاگت کی تاثیر کے حصول کے لئے بہت ضروری ہے۔ مشینی صنعت میں ایک سمجھدار پیشہ ور کی حیثیت سے ، آپ سمجھتے ہیں کہ آپ کے کاٹنے والے ٹولز کا معیار براہ راست آپ کے آؤٹ پٹ پر اثر انداز ہوتا ہے۔ اسی جگہ پر ہماری مہارت ایک سرکردہ مل فیکٹری کے طور پر کام میں آتی ہے۔ ہماری اعلی کارکردگی والے کاربائڈ اینڈ ملیں جدید مشینی کے غیر منقول ہیرو ہیں ، جو آپ کی پیداواری صلاحیتوں کو تبدیل کرنے کے قابل ہیں۔ چین پر مبنی ایک قابل اعتماد اینڈ مل سپلائر کا انتخاب کرکے ، آپ صرف ٹولز نہیں خرید رہے ہیں-آپ اپنی کمپنی کی مستقبل کی کامیابی میں سرمایہ کاری کر رہے ہیں۔

ہماری کاربائڈ اینڈ ملوں کا انتخاب کیوں کریں؟

اعلی مادی معیار

ہماری اختتامی ملوں کو پریمیم گریڈ کاربائڈ سے تیار کیا گیا ہے ، جس سے بے مثال سختی اور لباس مزاحمت کو یقینی بنایا گیا ہے۔ اس کا ترجمہ طویل آلے کی زندگی اور مستقل کارکردگی میں بھی ہوتا ہے ، یہاں تک کہ انتہائی مطالبہ کرنے والی ایپلی کیشنز میں بھی۔

درخواستوں کی حد

Whether you're working with tough alloys in aerospace or creating intricate molds for the automotive industry, our comprehensive range of carbide end mills is designed to meet your specific needs.

صحت سے متعلق مینوفیکچرنگ

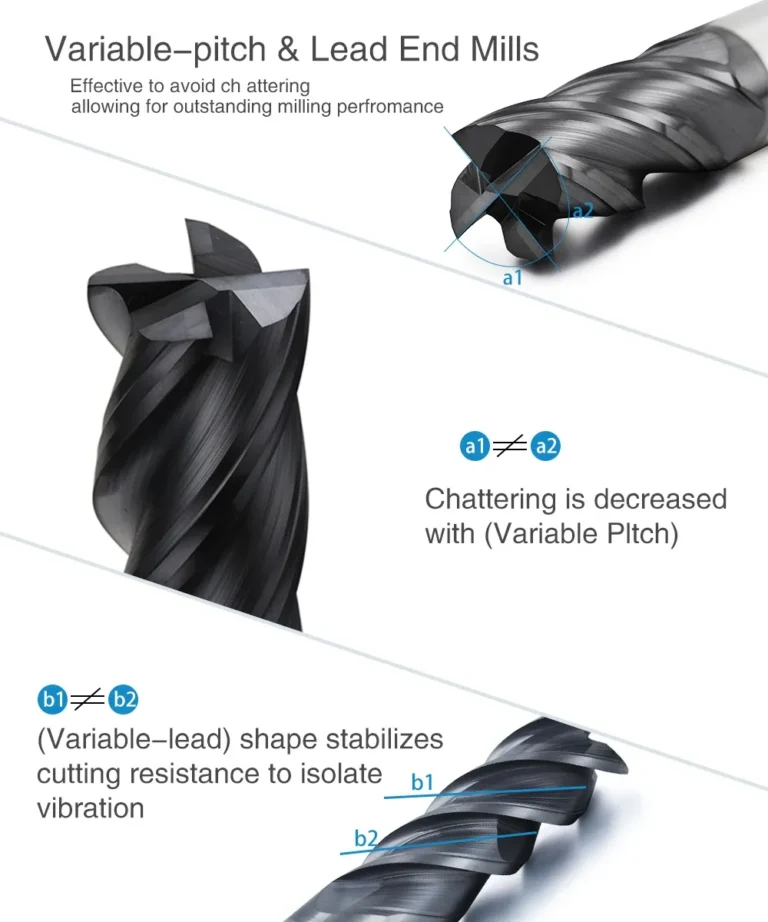

ایک معروف اینڈ مل فیکٹری کے طور پر ، ہم سخت رواداری اور اعلی سطح کی تکمیل کے ساتھ اختتامی ملوں کو تیار کرنے کے لئے جدید ترین سی این سی پیسنے والی ٹکنالوجی کو ملازمت دیتے ہیں۔ یہ صحت سے متعلق آپریشن کے دوران زیادہ سے زیادہ کاٹنے کی کارکردگی اور کم سے کم کمپن کو یقینی بناتا ہے۔

قابل اعتماد کاربائڈ اینڈ مل سپلائر کے ساتھ شراکت داری

When you choose us as your carbide end mill supplier, you're gaining more than just cutting tools. You're partnering with a solid carbide end mill manufacturer committed to your success. Our deep understanding of machining challenges, coupled with our state-of-the-art production facilities in China, allows us to offer tailored solutions that meet your specific needs.

صنعت سے متعلق حل

ایرو اسپیس

ہماری ایرو اسپیس گریڈ اینڈ ملوں کو سخت ترین مواد سے نمٹنے کے لئے انجنیئر ہیں ، جن میں ٹائٹینیم مرکب اور حرارت سے بچنے والے سپرلولوز (HRSA) شامل ہیں۔

آٹوموٹو

تیز رفتار پروٹو ٹائپنگ سے لے کر اعلی حجم کی پیداوار تک ، ہماری اینڈ ملیں آٹوموٹو انڈسٹری کی متنوع ضروریات کو پورا کرتی ہیں۔

میڈیکل

میڈیکل ڈیوائس مینوفیکچرنگ میں صحت سے متعلق سب سے اہم ہے۔ ہماری اختتامی ملیں اہم اجزاء کے لئے درکار درستگی اور سطح کے معیار کی فراہمی کرتی ہیں۔

ڈائی اور سڑنا

ہماری خصوصی ڈائی اور مولڈ اینڈ ملوں کا استعمال کرتے ہوئے آسانی کے ساتھ پیچیدہ جیومیٹری بنائیں ، جو توسیعی رسائ اور اعلی سطح کی تکمیل کے لئے ڈیزائن کیا گیا ہے۔

عام مشینی

ملازمت کی دکانوں اور عمومی مینوفیکچرنگ ایپلی کیشنز کے ل our ، ہماری ورسٹائل اینڈ ملیں آپ کو متنوع منصوبوں سے نمٹنے کے لئے لچک اور کارکردگی کی پیش کش کرتی ہیں۔

ایک معروف اینڈ مل فیکٹری کے ساتھ شراکت کا فائدہ

1 جدید ترین مینوفیکچرنگ کی سہولیات: چین میں ہماری جدید پیداوار کی سہولیات تازہ ترین سی این سی پیسنے والی مشینیں اور معائنہ کے سازوسامان سے لیس ہیں ، جس سے مستقل معیار اور سخت رواداری کو یقینی بنایا جاسکتا ہے۔

2 سخت کوالٹی کنٹرول: ہر سرے کی چکی میں ایک جامع کوالٹی کنٹرول عمل سے گزرتا ہے ، جس میں جہتی چیک ، مادی ساخت تجزیہ ، اور کارکردگی کی جانچ شامل ہے۔

3 مسلسل جدت اور r&d: ہماری سرشار ریسرچ اینڈ ڈویلپمنٹ ٹیم اختتامی مل کی کارکردگی کی حدود کو آگے بڑھانے کے لئے نئے مواد ، ملعمع کاری اور جیومیٹریوں کی مسلسل تلاش کرتی ہے۔

4 تخصیص کی صلاحیتیں: لچکدار اختتام مل ڈویلپر کی حیثیت سے ، ہم آپ کی مخصوص ضروریات کے حل کو تیار کرسکتے ہیں ، چاہے یہ ایک ترمیم شدہ معیاری ٹول ہو یا مکمل طور پر کسٹم ڈیزائن۔

چین پر مبنی اینڈ مل سپلائر کا انتخاب کیوں کریں؟

1 مسابقتی قیمتوں کا تعین: معیار پر سمجھوتہ کیے بغیر چین میں مینوفیکچرنگ کے لاگت کے فوائد کا فائدہ اٹھائیں۔ ہمارے موثر پیداوار کے عمل اور پیمانے کی معیشتیں ہمیں مسابقتی قیمتوں کی پیش کش کرنے کی اجازت دیتی ہیں۔

2 بڑی پیداوار کی گنجائش: چین میں ایک اہم اینڈ مل فیکٹری کے طور پر ، ہمارے پاس آسانی کے ساتھ چھوٹے پروٹو ٹائپ رنز اور اعلی حجم کے پیداواری آرڈر دونوں کو سنبھالنے کی صلاحیت ہے۔

3 گلوبل سپلائی چین انضمام: ہمارے اسٹریٹجک مقام اور اچھی طرح سے قائم لاجسٹک نیٹ ورک دنیا بھر میں صارفین کو بروقت ترسیل کو یقینی بناتے ہیں۔

4 معیار سے وابستگی: ہم اس تاثر کو چیلنج کرتے ہیں “چین میں بنایا گیا” مطلب کم معیار ہے۔ ہماری اختتامی ملیں بین الاقوامی معیارات پر پورا اترتی ہیں یا اس سے تجاوز کرتی ہیں ، جو دنیا کے بہترین سے مقابلہ کرتی ہیں۔

5 ٹکنالوجی میں مستقل سرمایہ کاری: چین میں ایک ممتاز اینڈ مل سپلائر کی حیثیت سے ہماری حیثیت ہمیں جدید ٹیکنالوجی میں مسلسل سرمایہ کاری کرنے کی اجازت دیتی ہے۔ جدت طرازی سے یہ عزم یقینی بناتا ہے کہ ہمارے مؤکلوں کو ہمیشہ کاربائڈ اینڈ مل ڈیزائن اور مینوفیکچرنگ میں جدید ترین پیشرفت تک رسائی حاصل ہے۔

فضیلت سے ہماری وابستگی

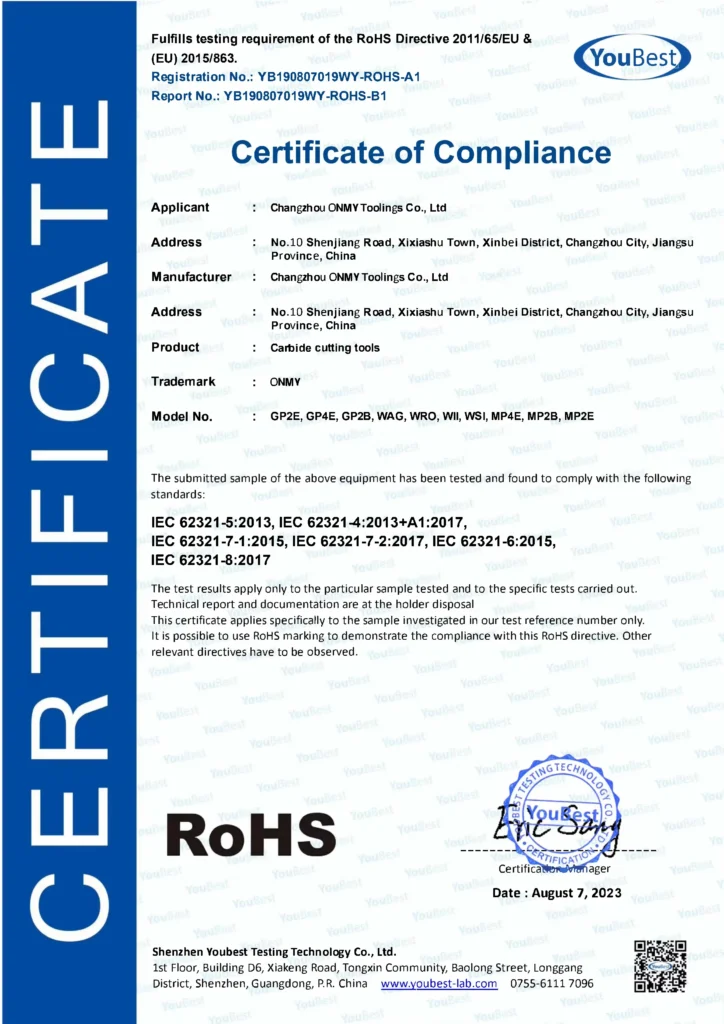

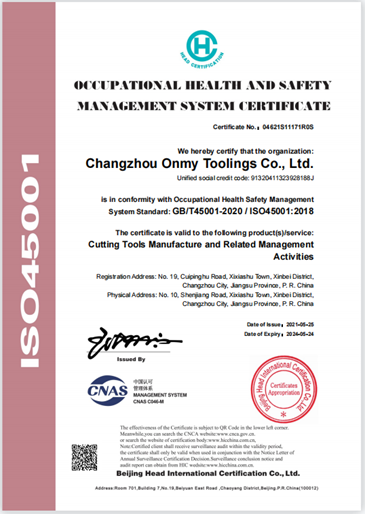

1 آئی ایس او سرٹیفیکیشن: ہمارے مینوفیکچرنگ کے عمل ISO 9001 مصدقہ ہیں ، جو تمام کاموں میں مستقل معیار کے انتظام کو یقینی بناتے ہیں۔

2 صنعت کی تعمیل: ہم صنعت سے متعلق معیارات اور ضوابط پر عمل پیرا ہیں ، بشمول ایرو اسپیس اور میڈیکل ڈیوائس مینوفیکچرنگ کے لئے۔

3 ماحولیاتی ذمہ داری: استحکام سے ہماری وابستگی ہمارے ماحول دوست مینوفیکچرنگ کے عمل اور فضلہ کے انتظام کے ذمہ دار طریقوں سے ظاہر ہوتی ہے۔

4 کسٹمر مرکوز نقطہ نظر: ہم اپنے مؤکلوں کے ساتھ طویل مدتی شراکت داری بنانے میں یقین رکھتے ہیں۔ ہماری ٹیکنیکل سپورٹ ٹیم ہمیشہ صحیح ٹولز کو منتخب کرنے اور اپنے مشینی عمل کو بہتر بنانے میں آپ کی مدد کرنے کے لئے تیار ہے۔

ہماری اختتامی ملوں کی کچھ خصوصیات

کاربائڈ اینڈ ملوں اور سپلائرز کے بارے میں عمومی سوالنامہ

کاربائڈ اینڈ ملز کیا ہیں اور وہ دوسرے مواد سے کیوں بہتر ہیں؟

Carbide end mills are cutting tools made from tungsten carbide, a compound of tungsten and carbon. They're superior to high-speed steel (HSS) end mills due to their higher hardness, better wear resistance, and ability to maintain sharpness at higher temperatures. This results in longer tool life, higher cutting speeds, and better surface finishes.

چین میں مقیم اینڈ مل ڈویلپر کے ساتھ کام کرنے کے کیا فوائد ہیں؟

Benefits include:Competitive pricing due to lower production costs ,Large manufacturing capacity ,Ability to handle both small and large orders ,Often equipped with state-of-the-art machinery ,Flexibility in customization ,Established global supply chains

کیا آپ کسٹم اینڈ مل حل فراہم کرسکتے ہیں؟

ہاں ، بہت ساری مل فیکٹریاں حسب ضرورت خدمات پیش کرتی ہیں۔ اس میں معیاری ٹولز یا مکمل طور پر کسٹم ڈیزائن میں ترمیم شامل ہوسکتی ہے۔ بہترین حل کا تعین کرنے کے ل your اپنے سپلائر سے اپنی مخصوص ضروریات پر تبادلہ خیال کریں۔

میں اپنی درخواست کے لئے دائیں سرے کی چکی کا انتخاب کیسے کروں؟

Selecting the right end mill depends on several factors:Material being machined Type of operation (roughing, finishing, slotting, etc.) Machine capabilities Required surface finish Tool life expectations Budget considerationsConsult with your carbide end mill supplier for expert recommendations based on your specific needs.

آپ کے کوالٹی کنٹرول کا عمل کس طرح مستقل مصنوعات کی کارکردگی کو یقینی بناتا ہے؟

A reputable carbide end mill supplier should have a rigorous quality control process that includes:Raw material testing ,In-process inspections ,Final dimensional checks ,Coating quality verification ,Performance testing ,Batch traceability.Ask your supplier about their specific quality control measures and certifications.

کیا کاربائڈ اینڈ ملوں کو دوبارہ تیار کیا جاسکتا ہے؟

ہاں ، بہت ساری کاربائڈ اینڈ ملوں کو اپنی کارآمد زندگی میں توسیع کرتے ہوئے ، اس میں نئی شکل دی جاسکتی ہے۔ تاہم ، اس عمل کے لئے خصوصی سامان اور مہارت کی ضرورت ہے۔ اپنے اختتامی مل سپلائر سے ان کی بحالی کی خدمات یا سفارشات کے بارے میں مشورہ کریں۔