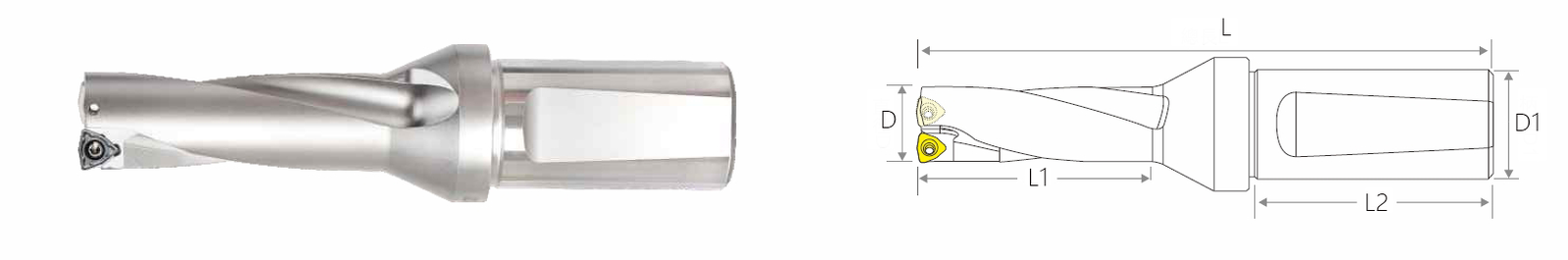

Uドリル2Dボディ20mmシャンクSPシリーズインサート付

1.SPシリーズの超硬チップを使用

2.2次元Uドリル本体

3.原料としてH13鋼を使用する。高い硬度、よい剛性率、傷つくこと容易ではない癒やすことの後で処理される。

4.二重スパイラル冷却構造、より長い挿入物の寿命。

- 刃先交換式超硬インサート: これが決定的な特徴である。Uドリルは、刃先として交換可能な超硬チップを利用している。これらのチップは通常、複数の切削ポイントを持ち、磨耗した場合は個別に回転または交換できるため、ドリルビット全体を再研磨または交換する必要がありません。これにより、ダウンタイムと工具コストが大幅に削減される。

- U字型フルート・デザイン: 特徴的なU字型のフルートは、効率的な切りくず排出のために最適化されています。この設計により、切削領域からの切り屑の排出がスムーズかつ迅速になり、切り屑の堆積を防ぎ、特に深穴での工具破損のリスクを低減します。

- スルーツールクーラントチャンネル: ほとんどのUドリルは、クーラントを刃先に直接供給する内部チャンネルを備えています。これにより、効果的な冷却と潤滑が行われ、熱の抑制、摩擦の低減、切り屑排出の改善、およびチップ工具寿命の延長に役立ちます。

- 硬質工具本体: ドリル本体は通常、焼入れ鋼で作られており、穴あけ加工中に高い剛性と安定性を提供します。この剛性により、従来のドリルに比べて高い切削速度と送り速度が可能になり、生産性の向上につながります。

- デュアルカッティングエッジ: Uドリルでは通常、センターチップとペリフェラルチップの2つのチップを使用します。この構成により、バランスの取れた切削力が確保され、真円度や真直度の向上など、穴品質の向上に貢献します。

- 自己中心能力: Uドリルの設計は、多くの場合、セルフセンタリング効果を提供し、多くの用途で、事前にドリルされたセンターホールを必要とせずに、ワーク上で直接穴あけを開始することを可能にする。

- 汎用性がある: さまざまなチップ形状と材種を利用できるUドリルは、鋼、ステンレス鋼、鋳鉄、アルミニウム、その他の非鉄金属など、さまざまな材料の加工に使用できます。

- ホールクオリティの向上: 剛性の高いボディ、効果的な切りくず排出、精密なチップの組み合わせにより、寸法精度、仕上げ面粗さ、真直度が向上した穴が得られ、多くの場合、ボーリングやリーマ加工などの二次仕上げ加工の必要性が低減または排除される。

| モデル番号 | (L1/D) | (L1) | (L) | (D) | D1/L2 | 挿入 | ネジ | レンチ |

|---|---|---|---|---|---|---|---|---|

| SP02-2D-8.5-C20A | 2D | 17 | 85 | 8.5 | 20/50 | SPMG020102 | M1.8×3.2L | T6 |

| SP02-2D-9-C20A | 2D | 18 | 86 | 9 | 20/50 | |||

| SP02-2D-9.5-C20A | 2D | 19 | 87 | 9.5 | 20/50 | |||

| SP04-2D-10-C20A | 2D | 20 | 88 | 10 | 20/50 | SPMG040202 | M1.8×4.0L | |

| SP04-2D-10.5-C20A | 2D | 21 | 89 | 10.5 | 20/50 | |||

| SP04-2D-11-C20A | 2D | 22 | 89.5 | 11 | 20/50 | |||

| SP04-2D-11.5-C20A | 2D | 23 | 90 | 11.5 | 20/50 | |||

| SP04-2D-12-C20A | 2D | 24 | 91 | 12 | 20/50 | SPMG040202 SPMG040204 | M1.8×4.0L | |

| SP04-2D-12.5-C20A | 2D | 25 | 92 | 12.5 | 20/50 | M2.0x5.5L | ||

| SP05-2D-13-C20A | 2D | 26 | 93 | 13 | 20/50 | SPMG05D204 | M2.2×5.5L | |

| SP05-2D-13.5-C20A | 2D | 27 | 94 | 13.5 | 20/50 | |||

| SP05-2D-14-C20A | 2D | 28 | 95 | 14 | 20/50 | |||

| SP05-2D-14.5-C20A | 2D | 29 | 96 | 14.5 | 20/50 | |||

| SP05-2D-15-C20A | 2D | 30 | 97 | 15 | 20/50 | |||

| SP05-2D-15.5-C20A | 2D | 31 | 98 | 15.5 | 20/50 | |||

| SP05-2D-16-C20A | 2D | 32 | 99 | 16 | 20/50 | |||

| SP05-2D-16.5-C20A | 2D | 33 | 100 | 16.5 | 20/50 | |||

| SP05-2D-17-C20A | 2D | 34 | 101 | 17 | 20/50 | |||

| SP05-2D-17.5-C20A | 2D | 35 | 102 | 17.5 | 20/50 | |||

| SP05-2D-18-C20A | 2D | 36 | 103 | 18 | 20/50 | |||

| SP05-2D-18.5-C20A | 2D | 37 | 104 | 18.5 | 20/50 | |||

| SP06-2D-19-C20A | 2D | 38 | 105 | 19 | 20/50 | SPMG060204 | M2.5x6L | T8 |

| SP06-2D-19.5-C20A | 2D | 39 | 106 | 19.5 | 20/50 | |||

| SP06-2D-20-C20A | 2D | 40 | 107 | 20 | 20/50 | |||

| SP06-2D-20.5-C20A | 2D | 41 | 108 | 20.5 | 20/50 | |||

| SP06-2D-21-C20A | 2D | 42 | 109 | 21 | 20/50 | |||

| SP06-2D-21.5-C20A | 2D | 43 | 110 | 21.5 | 20/50 | |||

| SP06-2D-22-C20A | 2D | 44 | 111 | 22 | 20/50 | |||

| SP06-2D-22.5-C20A | 2D | 45 | 112 | 22.5 | 20/50 | |||

| SP07-2D-23-C20A | 2D | 46 | 113 | 23 | 20/50 | SPMG07T308 | M2.5x7L | |

| SP07-2D-23.5-C20A | 2D | 47 | 114 | 23.5 | 20/50 | |||

| SP07-2D-24-C20A | 2D | 48 | 115 | 24 | 20/50 |