Standard tungsten carbide plates

Tungsten carbide plate, also known as carbide flat, is an ultra-hard material made from tungsten carbide and a metal binder. It offers high hardness, wear resistance, and corrosion resistance, widely used in various applications.

Applications and Scope:

Manufacturing cutting tools, such as blades and drills.

Mold production for stamping and drawing processes.

Wear-resistant components, like mining equipment and mechanical seals.

Industrial processing in high-strength, high-temperature environments.

Product Offering:

We provide standard tungsten carbide plates and can customize carbide flats based on customer requirements for size, shape, and performance to meet specific application needs.

Detailed Introduction to Tungsten Carbide Plate

Tungsten carbide plate, also known as carbide flat or cemented carbide plate, is a high-performance composite material primarily composed of tungsten carbide (WC) particles and a metal binder (such as cobalt) produced through powder metallurgy. Renowned for its exceptional hardness and wear resistance, it is often referred to as the “industrial teeth” and plays a critical role in modern manufacturing, maintaining stable performance under extreme conditions.

1. Composition

The primary component of a tungsten carbide plate is tungsten carbide (WC), which consists of equal parts tungsten (W) and carbon (C) atoms. Tungsten is a heavy metal with a high melting point (approximately 3422°C), while carbon contributes to its hardness. Pure tungsten carbide is brittle, so it is typically combined with 5%-20% of a metal binder (such as cobalt, nickel, or iron) to form cemented carbide. This composite structure balances hardness and toughness. The binder ratio can be adjusted based on the application—increasing cobalt content enhances toughness but may slightly reduce hardness.

2. Properties

Tungsten carbide plates are distinguished by their outstanding physical and mechanical properties, including:

- Durezza: With a Vickers hardness (HV) of 1500-2000, it is second only to diamond and approximately ten times harder than steel, making it ideal for wear-resistant applications.

- Wear and Corrosion Resistance: Excels in high-friction and corrosive environments, resisting acids, alkalis, and oxidation.

- Stabilità termica: Maintains performance at high temperatures (up to 1000°C) without deformation due to its high melting point.

- Toughness and Density: With a density of about 15 g/cm³, its toughness depends on the binder content, allowing it to withstand impacts without easy fracturing. These properties make tungsten carbide plates superior to conventional steel in demanding conditions, though their brittleness requires avoiding extreme impacts.

3. Manufacturing Process

Tungsten carbide plates are produced using powder metallurgy, with the following key steps:

- Raw Material Preparation: Tungsten and carbon powders are mixed and reacted at high temperatures (1400-2000°C) to form tungsten carbide powder.

- Binder Mixing: WC powder is blended with a metal binder (e.g., cobalt) to create a composite powder.

- Forming: The powder is pressed into plate-shaped blanks using cold or hot pressing.

- Sintering: The blanks are sintered at high temperatures (1300-1500°C) in a vacuum or hydrogen atmosphere to densify the material and form a solid plate.

- Post-Processing: Grinding, polishing, or coating is applied to achieve precise dimensions and surface finish. Precision control throughout the process ensures uniformity and consistent performance.

4. Applications

Tungsten carbide plates are versatile and widely used across various industries:

- Utensili da taglio: Used to manufacture blades, drills, and milling cutters for efficiently machining hard materials like steel and alloys.

- Mold Manufacturing: Employed as wear-resistant linings in stamping, drawing, and injection molds to extend service life.

- Wear-Resistant Components: Used in mining equipment (e.g., drill bits and crusher liners), mechanical seals, and pump valves to resist wear and corrosion.

- Other Industries: Applied in aerospace, oil drilling, and electronics for components in high-temperature, high-pressure environments, or as nozzles and protective plates. Its versatility makes tungsten carbide plates essential for improving production efficiency and reducing maintenance costs.

5. Product Offering

We provide standard tungsten carbide plates in various specifications to meet common industrial needs. Additionally, we offer customized carbide flats tailored to specific customer requirements, including size, shape, and performance characteristics, ensuring optimal performance for unique applications.

6. Quality Identification and Considerations

High-quality tungsten carbide plates should have a smooth, mirror-like surface without cracks, pores, or inclusions, and a uniform gray-black color. Density and hardness tests are common quality checks. When purchasing, choose reputable manufacturers and verify material purity to avoid premature failure due to inferior products.

In summary, tungsten carbide plates are indispensable in modern industry due to their unique properties. Understanding their composition, properties, and applications allows for better evaluation of their value in specific projects. For customization or further inquiries, consult a professional supplier.

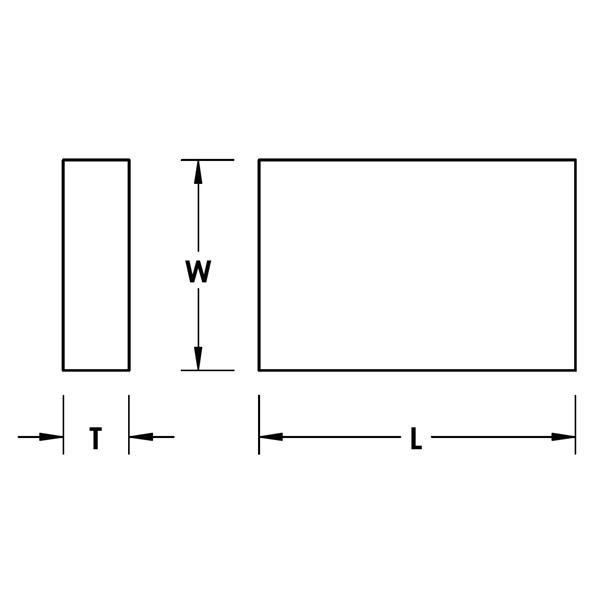

| T(Spessore) | W(larghezza) | L(lunghezza) | ||

|---|---|---|---|---|

| Finito (mm) | Tolleranza (mm) | Finito (mm) | Tolleranza (mm) | (mm) |

| 3 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 4 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 5 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 6 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 7 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 8 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 9 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 10 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 11 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 12 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 13 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 14 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 15 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 16 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 17 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 18 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 19 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |

| 20 | +0.5/+0.8 | 105 | +1.0/+1.5 | 105 |