U型鑽頭

U 型鑽頭,也稱為槍鑽或深孔鑽頭,是一種專用鑽孔工具,設計用於在各種材料上鑽深直孔。以下是U型鑽頭的要點:

- 設計:U 型鑽頭具有獨特的 U 形或半圓形凹槽,因此得名。這種設計與傳統麻花鑽的螺旋槽不同。

- 用途:它們主要用於鑽削高深徑比的深孔,在某些情況下通常為 3:1 到 100:1 以上。

- 優點:

- U 型槽可獲得出色的排屑效果

- 產生比傳統鑽頭更直的孔

- 深孔中較好的表面光潔度

- 可以獲得更高的進給率以提高生產力

警告

- 在車床上偏離中心使用時,U 型鑽頭很容易被燒毀。

- 使用小型U型鑽頭時,要求高速、大進給。進給量和速度越低,切削阻力越大,越容易燒刀。

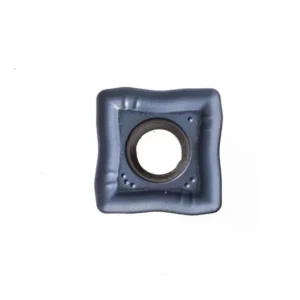

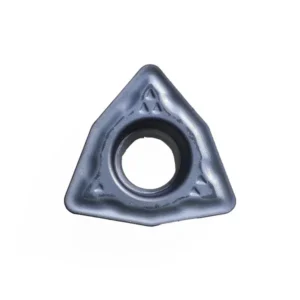

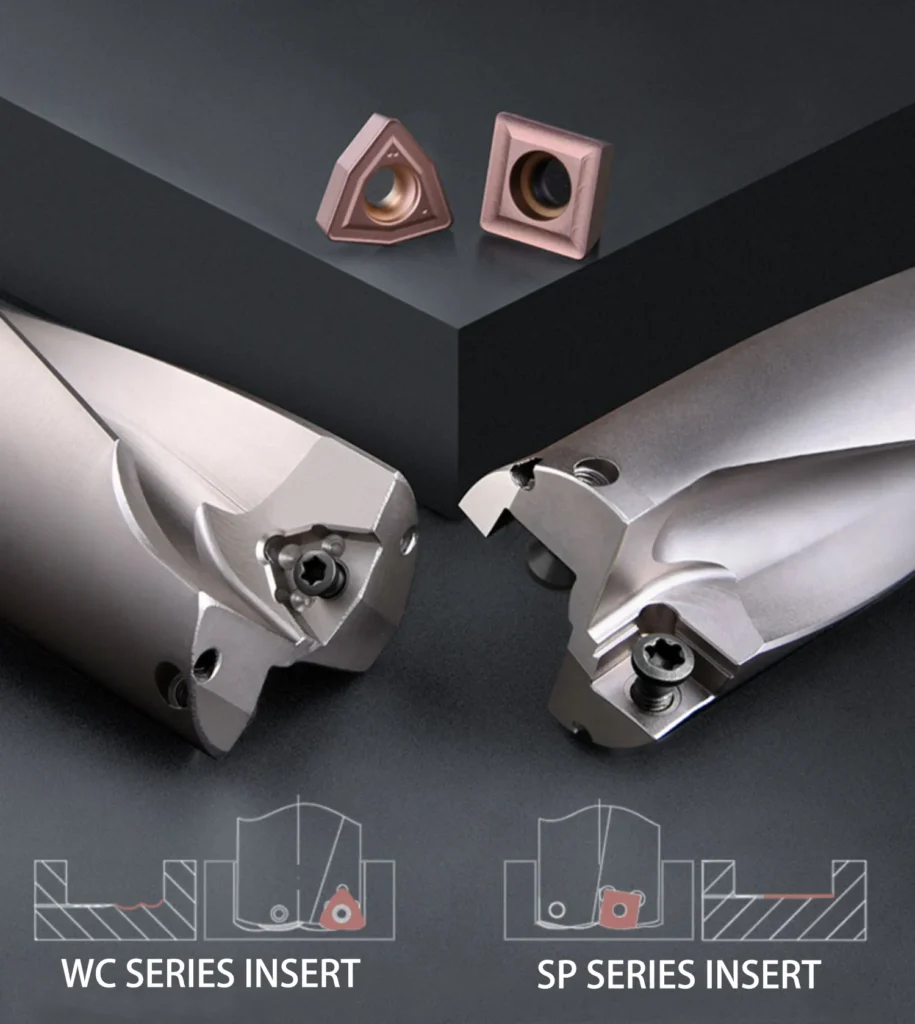

Different of WC&SP series insert

- WC系列加工效率更高

- SP系列加工光潔度較高

- WC系列刀片較便宜

- SP系列加工底面平面

- WC 系列刀片有 3 個切割刃。

- SP 系列刀片有 4 個切割刃。

針對更深的切屑成形器進行了最佳化

更快的排屑速度,直接影響加工效率,更深的排屑槽。在高進給和高速下的改進,仍能做到不積屑、不沾刀片、刃口倒角更小,優化並提高了U鑽體的剛性。

精密設計可抑製刀片擺動

精確的中心和周邊切削刃可有效抑制均勻受力加工時的振盪;降低難加工材料環境中刀具碰撞的風險,並提供比一般快速鑽頭更好的精度/穩定性。

注意:有周邊刃的刀片不能作為中心刃;同樣,中心邊緣刀片不能用作週邊邊緣;更換邊緣時請小心。

雙螺桿油孔高進給

雙螺旋油孔可保護刀片壽命並有助於冷卻鑽頭。快速鑽頭的尺寸越小,遵循高轉速/高進給以最小化切削阻力就越重要。

請與我們聯繫以獲取更多資訊!

U鑽加工常用公式

(數據僅供參考)

切削速度(Vc)

Vc= DC*π*n/1000

- Dc(mm) : 鑽頭直徑

- Vc(m/min):切削速度

- n(轉/分):轉速

例子

主軸轉速為1600rev/min,鑽頭直徑為20mm,切削速度為:Vc = Dc*π*n/1000 = 20*3.14*1600/1000 = 100(m/min)

進給速度(Vf)

Vf=Fr*n

- Vf(m/min):進給速度

- Fr(mm/rev):每轉進給量

- n(轉/分):主軸轉速

例子

主軸轉速為1350 min-1,鑽頭直徑為Ø12,求切削速度。

(回答)

代入公式

vf=f×n=0.2×1350=270mm/min

這使得主軸每分鐘進給量為 270mm/min。

孔加工時間(Tc)

Tc=ld*i/n*f

- Tc(min):加工時間

- i:孔數

- Fr(mm/rev):每轉進給量

- n(轉/分):主軸轉速

- ld:鑽孔深度

例子

在 SCM440 鋼上鑽一個 Ø15、30 毫米深的孔。切削速度為 50 m/min,每轉進給量為 0.15 mm/rev。求鑽孔時間。

(回答)

主軸轉速n=(50×1000)÷(15×3.14)=1061.57min-1

溫度 = (30 × 1) ÷ (1061.57 × 0.15) = 0.188

= 0.188 × 60 = 11.3 秒鑽孔。

金屬去除率(Q)

Q=Vc*Dc*Fn/4

- Vc(m/min):切削速度

- Dc(mm):鑽頭直徑

- Fn(mm/r):進給量

u 鑽頭參數

(數據僅供參考)

| 材料 | 硬度 | 切削速度 | U型鑽頭直徑 | |||

| 17.5-22 | 22.2-30 | 30.5-40 | 40.5-50 | |||

| 鋼 | 80-180 | 200-280 | 0.05-0.1 | 0.07-0.12 | 0.1-0.2 | 0.15-0.25 |

| 鋼 | 150-225 | 150-220 | 0.05-0.12 | 0.08-0.15 | 0.12-0.25 | 0.18-0.28 |

| 低合金鋼 | 150-260 | 160-220 | 0.06-0.12 | 0.08-0.18 | 0.15-0.3 | 0.2-0.3。 |

| 高合金鋼 | 150-240 | 120-180 | 0.05-0.1 | 0.06-0.15 | 0.12-0.2 | 0.18-0.25 |

| 不銹鋼 | 150-250 | 100-200 | 0.05-0.1 | 0.07-0.12 | 0.12-0.2 | 0.15-0.22 |

| 工具鋼 | 170-270 | 120-200 | 0.05-0.12 | 0.07-0.15 | 0.12-0.22 | 0.15-0.25 |

| 鑄鐵 | 160-220 | 120-180 | 0.1-0.17 | 0.15-0.2 | 0.18-0.25 | 0.2-0.3 |

| 合金鑄鐵 | 150-260 | 110-180 | 0.08-0.14 | 0.12-0.18 | 0.15-0.22 | 0.18-0.25 |

| 鋁合金 | 40-140 | 250-350 | 0.075-0.15 | 0.1-0.18 | 0.15-0.25 | 0.18-0.3 |

| 鑄鋁 | 50-150 | 220-280 | 0.1-0.2 | 0.15-0.22 | 0.18-0.3 | 0.22-0.35 |

u 鑽頭加工能力要求

為了真正發揮U鑽的加工效果,除了刀柄和刀片之外,還需要合適的機床,這樣才能發揮U鑽的真正加工能力。

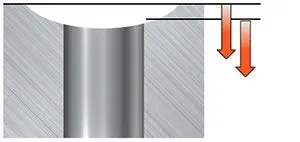

不規則表面鑽孔

不規律的

- 盡可能使用最短的鑽頭,以最大限度地減少振動趨勢並減少偏轉的影響

- 切削速度的建議起始值和建議的最低進給量

- 當凹面半徑等於或小於鑽頭半徑時,不建議使用 6–7×DC

凸面

- 盡可能使用最短的鑽頭,以最大限度地減少振動趨勢並減少偏轉的影響

- 切削速度的建議起始值和建議的最低進給量

- 當凹面半徑等於或小於鑽頭半徑時,不建議使用 6–7×DC

凹

- 盡可能使用最短的鑽頭,以最大限度地減少振動趨勢並減少偏轉的影響

- 切削速度的建議起始值和建議的最低進給量

- 當凹面半徑等於或小於鑽頭半徑時,不建議使用 6–7×DC

跨孔鑽

- 對於不同直徑的孔:先鑽較大的孔以減少毛邊的形成

- 在過孔期間從建議的最低進給開始

- 不建議用於長切屑材料,因為在穿過孔洞時會排屑

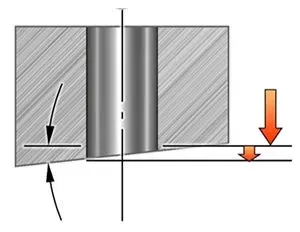

成角度或傾斜的表面、入口

- 盡可能使用最短的鑽頭,以最大限度地減少振動趨勢並減少偏轉的影響

- 從建議的最低切削速度和建議的最低進給量的 1/3(或更低)開始,直到完全嚙合,然後返回正常進給量

- 4–5×DC 傾斜入口的角度最大可達 15°

- 6–7×DC 傾斜入口的角度最大可達 10°

有角度或傾斜的表面,出口

- 盡可能使用最短的鑽頭,以最大限度地減少振動趨勢並減少偏轉的影響

- 切削速度的建議起始值和建議的最低進給量(或更低)

- 4–5×DC 傾斜出口的角度最大可達 15°

- 6–7×DC 傾斜出口的角度最大可達 5°

不對稱曲面鑽孔

- 使用盡可能短的鑽頭,以盡量減少鑽頭從中心向外的彎曲,類似於傾斜表面

- 對於凹面,將進給量減少至初始鑽進速度的 1/3

- 曲面半徑應大於鑽頭半徑

- 不建議用於 6–7×DC 鑽頭

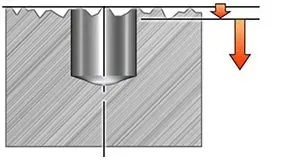

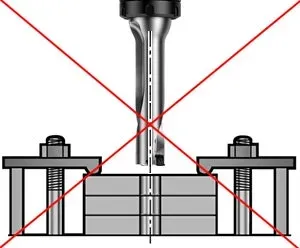

預鑽孔

- 為了使中心和周邊刀片之間的切削力平衡在可接受的水平上,預鑽孔不應大於DC/4

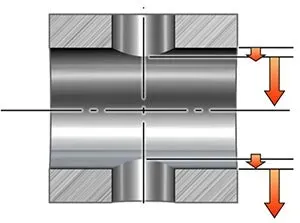

疊鑽

- 最大限度地減少堆疊板之間的間隙對於成功進行堆疊鑽孔至關重要。這可以透過將板夾緊或焊接在一起來完成。一個很好的常見做法是在板之間插入工業用紙(厚度約為 0.5-1 毫米(0.020-0.039 英吋)),以消除任何不規則並抑制振動。由於鑽孔過程中的軸向力將達到數千牛頓,因此夾緊支撐是一個重要的考慮因素。

聯絡 ONMY 開展您的業務

看看我們的一些客戶如何看待我們的商品和服務:

我們的優勢

- 新原料,第一步把控產品品質。

- 廠商直銷,拒絕中間商賺差價。

- 6S管理,標準化流程,從源頭杜絕問題產品出廠。

- 專業的銷售專家解決您的大部分加工問題。

- 售後保固任何產品問題7*24小時服務。