In the world of precision machining, tapered ball nose end mills have emerged as indispensable tools for creating complex, three-dimensional surfaces with unparalleled accuracy. These versatile cutting tools combine the benefits of tapered end mills with the smooth finishing capabilities of ball nose end mills, making them ideal for a wide range of applications. In this comprehensive guide, we’ll explore the intricacies of tapered ball nose end mills, with a particular focus on optimizing feeds and speeds for maximum efficiency and quality.

Understanding the Unique Design of Tapered Ball Nose End Mills

Tapered ball nose end mills are characterized by their distinctive geometry, which features a gradually decreasing diameter along the cutting length, culminating in a hemispherical tip. This unique design offers several advantages over traditional end mills:

- Improved rigidity: The tapered shape provides enhanced stiffness, reducing tool deflection during machining.

- Better chip evacuation: The taper allows for more efficient chip removal, especially in deep cavity milling.

- Increased reach: The tapered profile enables access to tight corners and deep pockets.

- Smooth surface finish: The ball nose tip ensures a superior finish on contoured surfaces.

Applications and Advantages

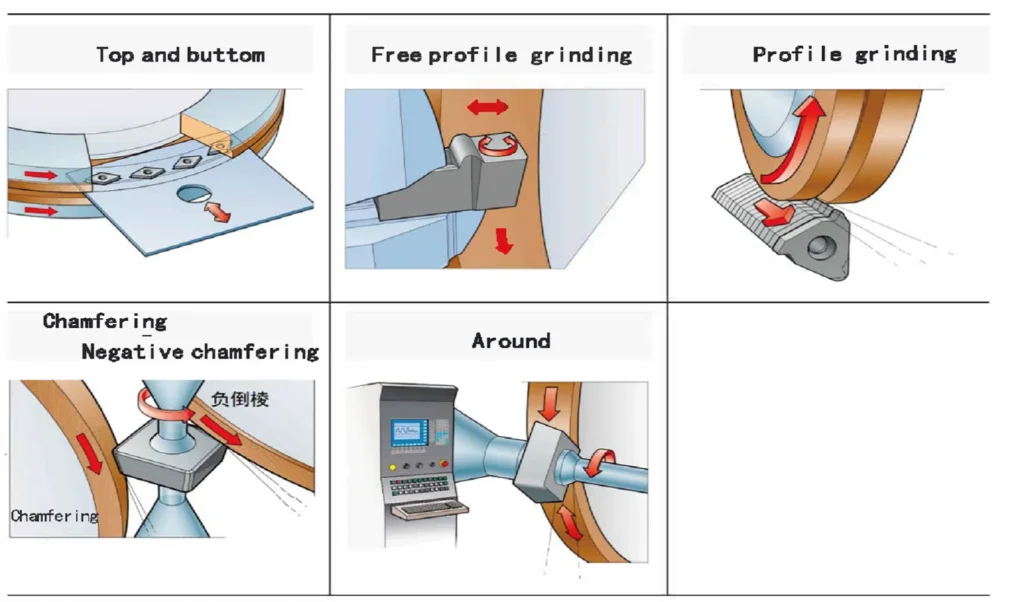

Tapered ball nose end mills excel in various machining operations, including:

- 3D contouring and surface finishing

- Mold and die making

- Aerospace component manufacturing

- Medical device production

- Artistic and sculptural work

The versatility of these tools makes them invaluable for machinists working on complex parts with intricate geometries.

Selecting the Right Tapered Ball Nose End Mill

Choosing the appropriate tapered ball nose end mill for your specific application is crucial for achieving optimal results. Consider the following factors:

- Material compatibility

- Taper angle and length

- Ball nose diameter

- Number of flutes

- Coating type

Each of these elements plays a role in determining the tool’s performance and longevity.

Optimizing Feeds and Speeds

One of the most critical aspects of using tapered ball nose end mills effectively is setting the correct feeds and speeds. Let’s delve into the factors that influence these parameters and how to calculate them for optimal performance.

Factors Affecting Feeds and Speeds

Several variables impact the ideal feeds and speeds for tapered ball nose end mills:

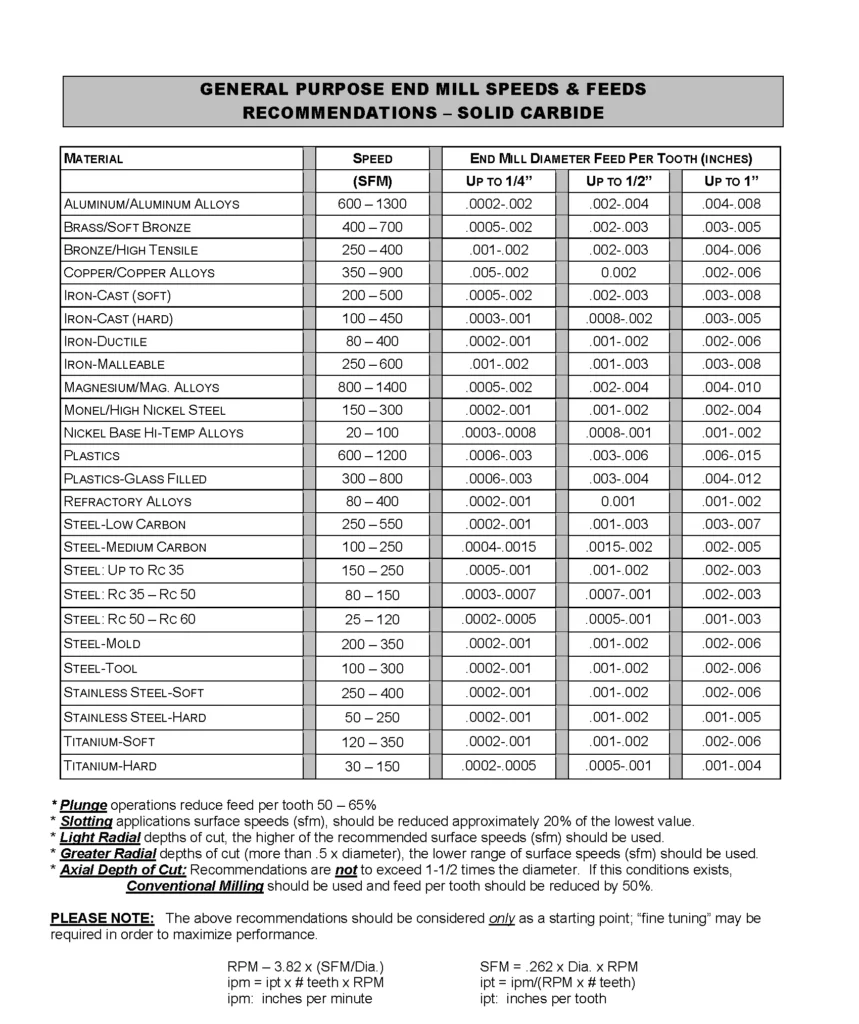

- Workpiece material

- Tool material and coating

- Depth of cut

- Stepover distance

- Machine capabilities

- Cutting strategy (climb vs. conventional milling)

Calculating Optimal Feeds and Speeds

To determine the best feeds and speeds for your tapered ball nose end mill, follow these steps:

- Determine the recommended surface feet per minute (SFM) for your tool and workpiece material combination.

- Calculate the spindle speed (RPM) using the formula: RPM = (SFM x 3.82) / Tool Diameter

- Establish the chip load (feed per tooth) based on the tool manufacturer’s recommendations.

- Calculate the feed rate using the formula: Feed Rate = RPM x Number of Flutes x Chip Load

It’s important to note that these calculations serve as a starting point. Fine-tuning based on actual machining results is often necessary for optimal performance.

Common Mistakes to Avoid

When setting feeds and speeds for tapered ball nose end mills, be wary of these common pitfalls:

- Overlooking the effective cutting diameter at different depths

- Neglecting to adjust speeds for different materials

- Using excessive depth of cut or stepover

- Failing to account for machine limitations

Best Practices for Using Tapered Ball Nose End Mills

To maximize the performance and lifespan of your tapered ball nose end mills, consider these best practices:

- Use climb milling when possible for better surface finish and tool life

- Implement proper toolpath strategies to maintain consistent engagement

- Utilize high-speed machining techniques for improved efficiency

- Employ appropriate coolant or lubrication methods

Maintenance and Care

Proper maintenance of tapered ball nose end mills is essential for ensuring consistent performance and longevity. Regular inspection, cleaning, and proper storage can significantly extend the life of these precision tools.

Troubleshooting Common Issues

Even with optimal feeds and speeds, issues may arise when using tapered ball nose end mills. We’ll discuss common problems such as chatter, poor surface finish, and premature tool wear, along with solutions to address these challenges.

Future Trends in Tapered Ball Nose End Mill Technology

As machining technology continues to evolve, so do tapered ball nose end mills. We’ll explore emerging trends in tool design, materials, and coatings that promise to enhance the capabilities of these versatile cutting tools.

結論

Mastering the use of tapered ball nose end mills, particularly in terms of optimizing feeds and speeds, is crucial for achieving superior machining results. By understanding the unique characteristics of these tools and implementing best practices, machinists can unlock their full potential across a wide range of applications. As technology advances, tapered ball nose end mills will undoubtedly play an increasingly important role in the world of precision manufacturing.