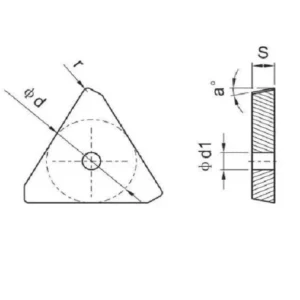

TPKN 銑刀片

TPKN insert is another type of cutting insert used in machining operations, particularly in turning and milling.

TPKN Insert Specification Guide

- T: This usually refers to the shape of the insert. In this case, ‘T’ 通常代表 “Triangle” 形狀。

- P: Often indicates a specific angle or clearance feature of the insert. In many cases, it denotes a positive rake angle.

- K: This could refer to the insert’s tolerance class or a specific feature of the cutting edge.

- N: Might indicate the absence of a chip breaker or a particular nose radius.

TPKN Insert Cutter Compatibility

TPKN inserts are generally known for their versatility and are often used in both turning and milling operations. The triangular shape provides three cutting edges, allowing for extended use before replacement is necessary. These inserts are often favored for their ability to handle a variety of cutting conditions and materials.

These inserts are typically used in operations requiring good chip control and surface finish, and they’re often suitable for machining steel, stainless steel, and cast iron, among other materials.

應用領域

刀片在各種工業銑削加工中表現出色:

- 普通面銑

- 方肩銑

- 粗加工和精加工工序

- 適用於鋼、不銹鋼和鑄鐵等材料

為什麼選擇我們的刀片?

Dual-Purpose Versatility

Our TPKN inserts excel in both turning and milling operations, reducing the need for multiple insert types and simplifying your tooling inventory.

Triple-Edge Economy

With three cutting edges per insert, our TPKN design offers excellent value, significantly lowering your tooling costs over time.

減少切割力

The positive geometry decreases cutting forces, making these inserts ideal for machining less rigid workpieces or when using less powerful machines.

Technical Support

Our team of machining experts is always available to provide guidance on optimal use and application-specific advice, ensuring you maximize the benefits of our TPKN inserts.

我們的生產能力