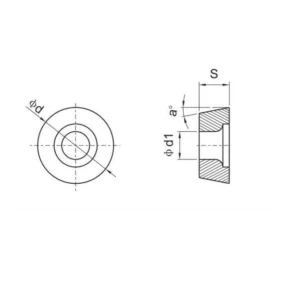

RPMT銑刀片

Are you seeking cutting tools that deliver unmatched precision, durability, and versatility? RPMT inserts are engineered to meet the highest standards in machining, offering exceptional performance across various applications. Learn how RPMT inserts can transform your manufacturing processes and drive superior results.

- 右: Indicates the shape of the insert, typically round in the case of RPMT inserts.

- 磷: Designates the insert’s tolerance class.

- 中號: Refers to the clamping method or chipbreaker style.

- 時間: Represents the thickness of the insert or specific features related to the design.

Why RPMT Are the Ideal Choice for Your Business

傑出的精度和準確性

RPMT inserts are designed with advanced geometries to ensure precise cutting and high accuracy in your machining operations. Their design guarantees that you achieve the exact specifications and tight tolerances required for high-quality outcomes.

好處:

- Achieve precise cuts and detailed results.

- 減少對返工和更正的需求。

較高的耐用性和壽命

Constructed from high-quality carbide or cermet and equipped with advanced coatings, RPMT inserts are built to withstand demanding conditions. Their durability translates to a longer tool life and fewer insert changes.

好處:

- 忍受高切削力和溫度。

- 最小化工具更換和相關的停機時間。

多種應用

RPMT inserts are versatile and suited for a wide range of machining tasks, including:

- 車削操作: 粗糙和整理過程的理想選擇。

- 銑削操作: 對於面部銑削,插槽和分析有效。

- 切槽和切斷: Suitable for internal and external grooving, as well as parting off operations.

好處:

- 適應各種材料和切割條件。

- 通過處理多個應用程序來簡化工具清單。

先進塗料和材料

RPMT inserts come with high-grade coatings such as PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition), which enhance wear resistance and cutting performance. These coatings help reduce friction and improve tool efficiency.

好處:

- Improve tool longevity and performance.

- Ensure consistent results in diverse machining environments.

Choosing the Right RPMT Insert

To select the appropriate RPMT insert for your application, consider:

- 材料: The type of material being machined (e.g., steel, stainless steel, cast iron).

- 操作類型: The specific machining operation (e.g., turning, milling, grooving).

- Cutting Conditions: Factors such as cutting speed, feed rate, and depth of cut.

- Insert Geometry and Coating: Choose based on required performance and application needs.

我們的生產能力