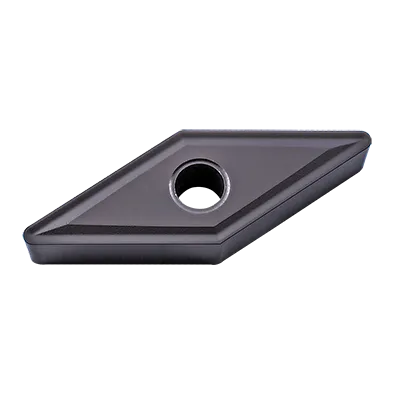

VNMG車刀

VNMG insert Angle :35 Degree 0° Negative Rake Insert with double-sided Chipbreaker;

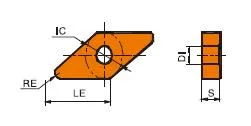

Dimensions: IC:9.525mm;LE:11mm/16.6mm;RE0.4mm/0.8mm/1.2mm;

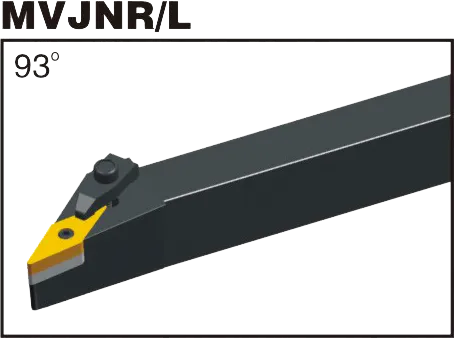

Matching VNMG Insert Holder: MVVNN, MVJNR/L;

VNMG insert sizes:(ISO) VNMG 12t304/VNMG160402/ VNMG160404/ VNMG160408;

(ANSI) VNMG330/ VNMG330.5/ VNMG331/ VNMG332/ VNMG431/ VNMG432;

It can deal with multiple operations by combining different chip breakers and grades;

產品介紹

VNMG Insert is made of high quality alloy metal with advanced technology.

The surface is treated with special coating to extend the using life.

The unique V shape design with negative angles of the VNMG Insert guarantees efficient machining and high stability.

The combination of different chip breakers and grades will help it to deal with different working condition and multiple operations.

In addition, it has the advantages of high hardness, high efficiency, high accuracy, corrosion resistance, long service life, smooth appearance as well as high quality.

主要特點

- 形狀: VNMG inserts are triangular with a 35° included angle, providing a good balance between strength and sharpness. This shape offers three usable cutting edges.

- Negative Rake Angle: The cutting face slopes backward from the cutting edge, providing a strong, durable edge well-suited for tougher materials and interrupted cuts.

- 間隙角: Typically 7° to help prevent rubbing against the workpiece.

- 斷屑槽: VNMG inserts often feature chipbreaker geometries to control chip formation and flow during machining, tailored to specific applications.

- 塗料: Often coated with materials like TiN, AlTiN, and others to improve wear resistance and tool life.

VNMG insert Specification

Understanding the VNMG Code

The letters and numbers in the VNMG designation signify important details:

- 五: 35° rhombic (diamond) shape

- 紐: Negative rake angle

- 中號: 公差等級(表示尺寸精度)

- 克: Indicates hole type and chipbreaker design (varies by manufacturer)

- 數字:

- Usually, the first two numbers represent the inscribed circle (size of the triangle) in sixteenths of an inch (or directly in millimeters for ISO codes).

- 第三個數字代表厚度(以十六分之一英吋為單位)。

- 最後一個數字通常表示刀尖半徑(越小意味著越鋒利)。

VNMG insert holder

硬質合金 VNMG 刀片尺寸(ISO 和 ANSI)

| vnmg insert full form | ||||

|---|---|---|---|---|

| ISO 名稱 | ANSI 名稱 | 內切圓 (IC) | 厚度 | 轉角半徑 |

| VNMG 160404 | VNMG331 | 16mm (0.63") | 4.76mm (0.187") | 0.4mm (0.016") |

| VNMG 160408 | VNMG332 | 16mm (0.63") | 4.76mm (0.187") | 0.8mm (0.031") |

| VNMG 160412 | VNMG333 | 16mm (0.64") | 4.76mm (0.188") | 1.2MM(0.047'') |

Example: VNMG 160408 (ISO)

- 35° triangular shape, negative rake insert.

- 內切圓 12.7mm(約 1/2″)。

- 厚度 4.76mm(約 3/16″)。

- 特定的斷屑槽/孔設計。

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

硬質合金刀片是目前最通用、最耐用的切削工具之一。但它們是如何製作的呢?是什麼讓他們如此強大?在本影片中,我們將探索硬質合金刀片背後的科學,從碳化鎢的特性到製造流程。

我們的生產能力

在現代製造業中,高性能硬質合金刀片是不可或缺的工具,為高效、精確的金屬加工奠定了基礎。然而,這些特殊的插入物並不是自行存在的。他們得到了先進機械的堅定支持。