單刃立銑刀

這是一套用於工業銑削應用中的單笛末端切割工具。它的應用,幾何形狀和製造中的鑽頭與鑽頭有區別。單笛末端磨坊用於高速銑削中的優質芯片疏散。這些末端磨坊由碳化鎢製成,碳化碳硫化物將耐受更多的熱量,同時仍然保持良好的硬度。它們只有一個前沿,在鋁,MDF,實木,塑料和丙烯酸中具有明顯的優勢。

應用

- 雕刻機,CNC路由器機-3軸,4個軸和5個軸(雕刻機和CNC機器-3軸,4軸,5軸)

- 應用:切木,塑料和丙烯酸板的西裝

特徵

- 這 立銑刀 套裝由高質量的碳化鎢製成,可提供良好的硬度和鋒利的尖端。

- 3.175mm — 1/2英寸的標準柄直徑適合許多銑床或CNC切割機。

- 帶有鋒利尖端的單笛設計的端磨機將提供平滑的切割表面和芯片清除。

- 通常,末端磨坊用於切割丙烯酸,PVC,MDF,密度板,木材和許多其他軟材料。

- 混合 &匹配模型號。一批是可以接受的。

- 對於分銷商,我們可以將您的品牌標記在刀具和塑料盒上。

- 混合 &一批工具的匹配塗層是可以接受的。

- Altin,Tialn,Tisin,Tin,DLC(Diamond Coating),Nano和Diamond供您選擇贏得競爭對手。

- HS代碼參考供您控制所有內容:8207709000。

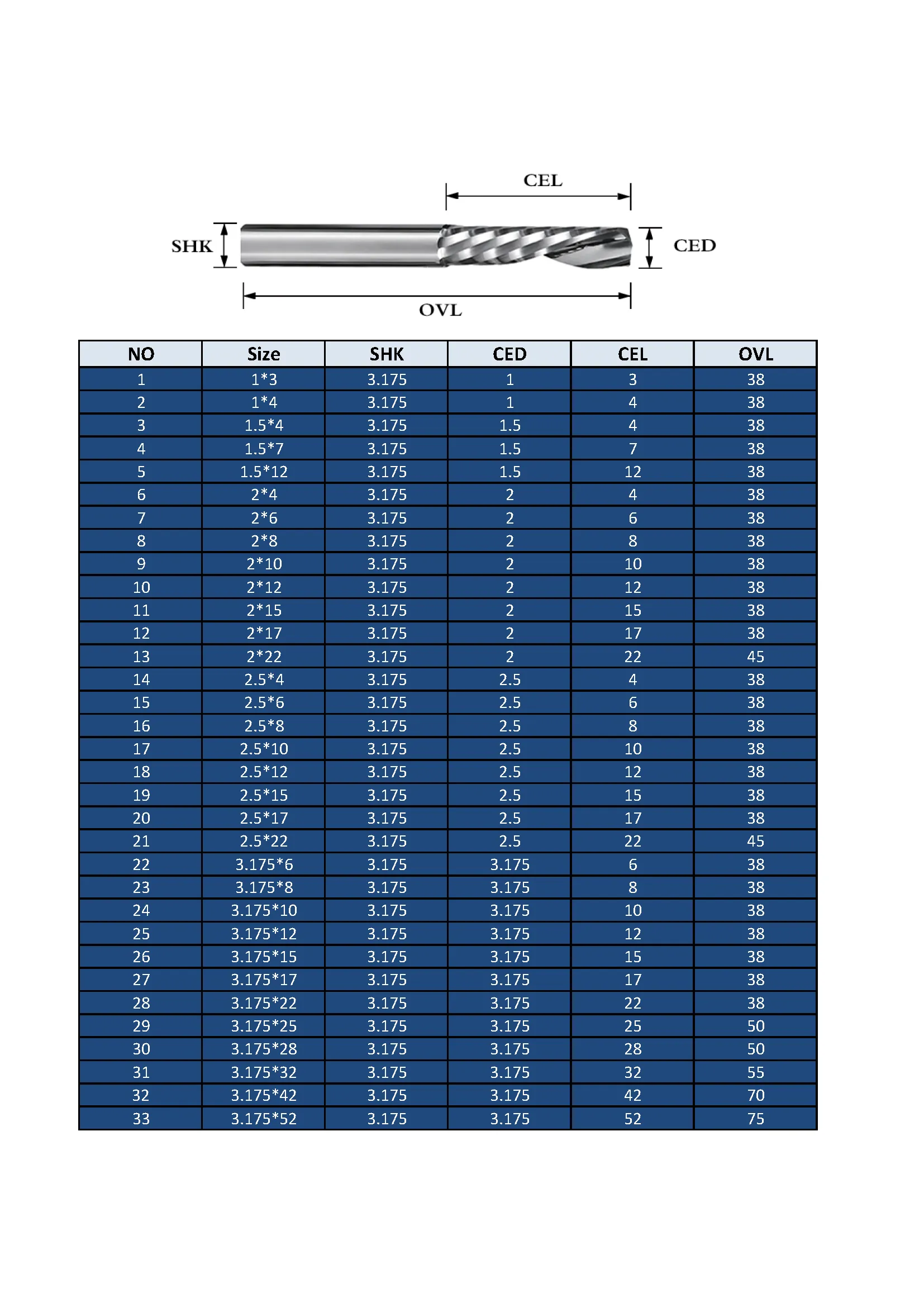

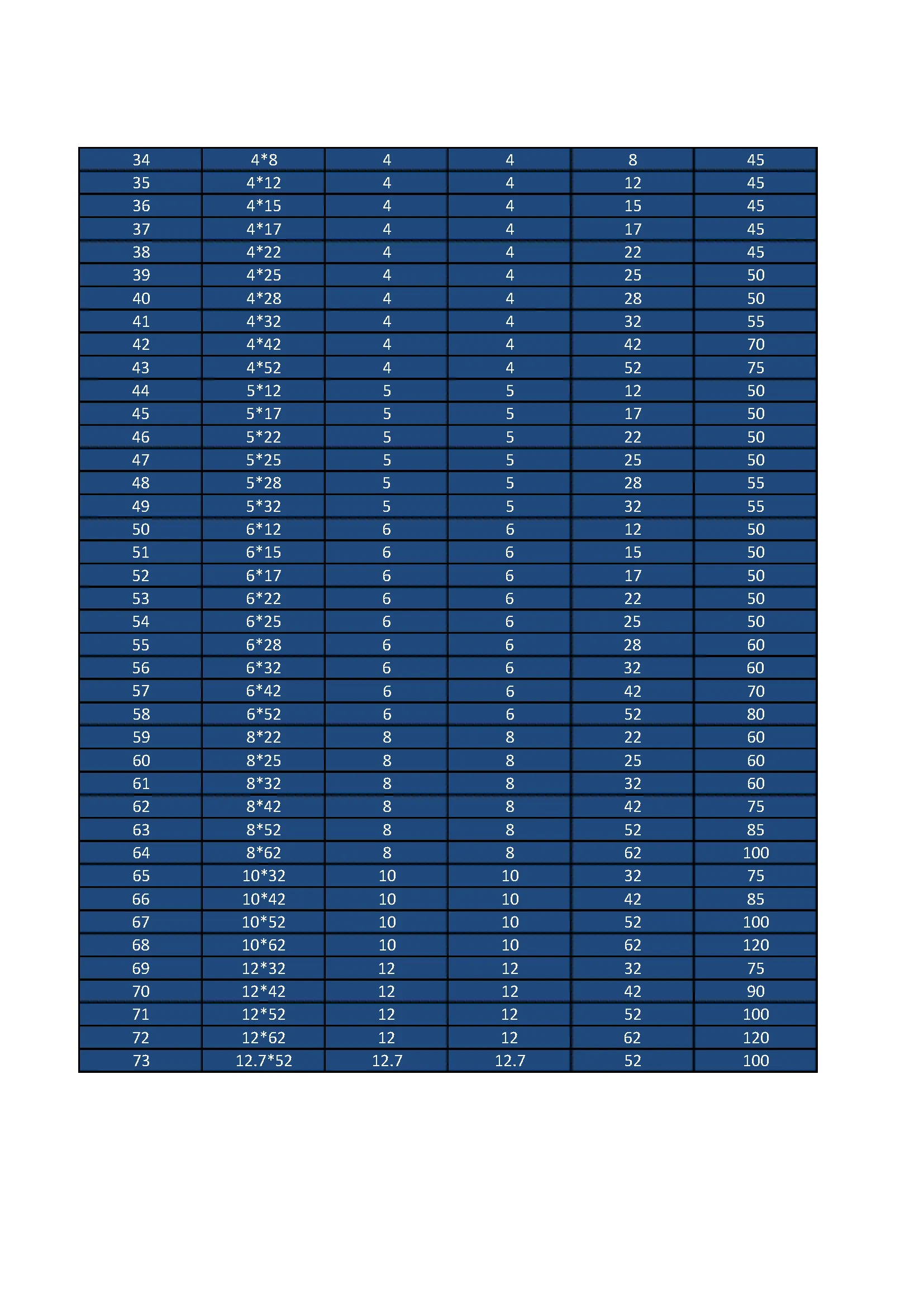

單笛末端磨機目錄

ONMY TOOLINGS 的差異

是什麼讓我們的單槽立銑刀與眾不同?這是我們獨特的組合:

先進的硬質合金配方

我們使用針對強度和耐磨性進行最佳化的專有微晶碳化物混合物。

創新的幾何形狀

我們專利的槽設計可最大限度地排屑並最大限度地減少切削力。

尖端塗料

我們採用奈米層狀 PVD 塗層來增強耐熱性並減少摩擦。

精密研磨

我們的多軸 CNC 磨床的公差可達 ±0.0005 英吋。

Don't just take our word for it. Here's what our satisfied customers have to say:

我快樂的客戶!

We've been using ONMY TOOLINGS's single flute end mills for over a year now, and the results are incredible. Our tool life has increased by 40%, and the surface finish quality is unmatched. The custom single flute ball end mills we ordered were a game-changer for our complex 5-axis machining projects. The support from their engineering team was top-notch."

莎拉L。

Precision Parts Ltd 的 CNC 程式設計師

立即取得您的客製報價!

附:我們是否提到我們提供批量折扣?訂購越多,節省越多!

- 無與倫比的工廠直銷定價:省去中間商,與零售價相比可節省高達 40%。我們高效的製造流程使我們能夠以具有競爭力的價格提供優質的產品。

- 閃電般的快速交付:憑藉我們簡化的生產流程,我們提供業界領先的周轉時間。只需 7 天即可獲得客製化立銑刀!我們擁有大量標準尺寸庫存,可立即出貨。

- 個人化服務:我們的專家工程師團隊隨時準備協助您找到應對獨特加工挑戰的完美解決方案。我們提供免費諮詢來分析您的特定需求並推薦理想的工具規格。

經常問的問題

鋁,MDF,實木,塑料和丙烯酸。

單笛末端磨坊在軟材料的高速加工上表現出色,優先考慮材料去除速率和表面飾面。 Double Flute End Mills提供了更廣泛的選擇,適用於更廣泛的材料,並提供芯片拆卸和工具強度的平衡。