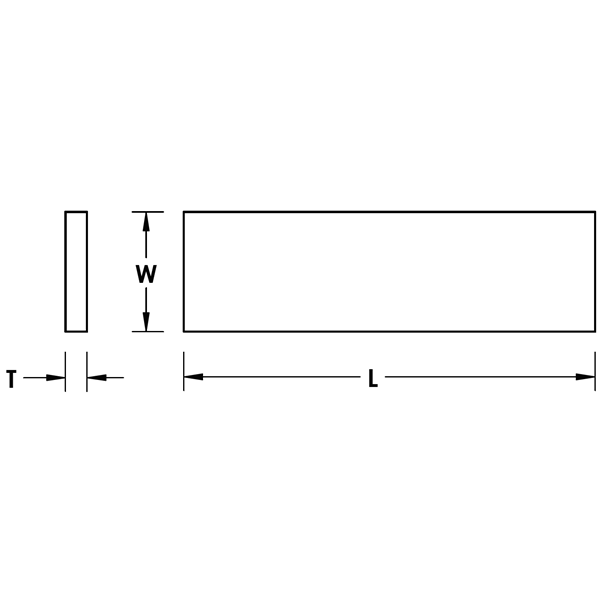

STB tungsten carbide strips

“STB”: Generally understood as a designation or grade, it often refers to standard rectangular-cross-section carbide products. In English, it is often interpreted as an abbreviation for “Standard Tool Blank.”

“Strip”: Refers to the shape, which is a rectangular strip of material.

Of course, you can still customize different sizes, which is easy for us to do.

Tungsten carbide strips, manufactured using a powder metallurgy process, offer a unique combination of properties that surpass many other materials. Tungsten carbide’s inherent hardness, approaching that of diamond, enables it to form a cutting edge that remains sharp even under high stress and high temperature. A cobalt binder provides the necessary toughness, preventing the otherwise brittle carbide from fracturing under impact.

The versatility of STB tungsten carbide strips are reflected in their wide range of applications. In the woodworking and metalworking industries, they are used in cutting tool blades, saw teeth, and planer blades for their ability to provide clean, precise cuts over time. Their wear and corrosion resistance also make them ideal for manufacturing wear-resistant components such as nozzles, guides, and plates used in various machinery.

STB tungsten carbide strips are available in a variety of grades, each with a different ratio of tungsten carbide to cobalt and grain size. This allows them to tailor their properties to specific applications. For example, higher cobalt content generally results in greater toughness, making the strip more suitable for high-impact applications. Conversely, lower cobalt content and finer grains result in increased hardness and wear resistance, making them ideal for precision cutting tools. The manufacturing process includes high-temperature pressing and sintering to ensure that the final product is dense and uniform with reliable performance.

| STB | Metric | Inch | |||||||

|---|---|---|---|---|---|---|---|---|---|

| T(Thickness)mm | Tolerance(+1.5mm) | W(Width)mm | Tolerance(+1.5mm) | L(Length)mm | Tolerance(+1.5mm) | T(Thickness)inch | W(Width)inch | L(Length)inch | |

| STB-12 | 0.8 | +0.3/+0.1 | 1.6 | +0.4/+0.2 | 25.4 | +0.6/+0.2 | 1/32 | 7/16 | 1 |

| STB-13 | 1.2 | +0.3/+0.1 | 2.4 | +0.4/+0.2 | 25.4 | +0.6/+0.2 | 3/64 | 3/32 | 1 |

| STB-13A | 1.2 | +0.3/+0.1 | 2.4 | +0.4/+0.2 | 20.6 | +0.6/+0.2 | 3/64 | 3/32 | 13/16 |

| STB-24A | 1.6 | +0.3/+0.1 | 3.2 | +0.4/+0.2 | 25.4 | +0.6/+0.2 | 1/16 | 1/8 | 1 |

| STB-24B | 1.6 | +0.3/+0.1 | 3.2 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 1/16 | 1/8 | 3 |

| STB-24C | 1.6 | +0.3/+0.1 | 3.2 | +0.4/+0.2 | 31.8 | +0.6/+0.2 | 1/16 | 1/8 | 11/4 |

| STB-26A | 1.6 | +0.3/+0.1 | 4.8 | +0.4/+0.2 | 25.4 | +0.6/+0.2 | 1/16 | 3/16 | 1 |

| STB-26C | 1.6 | +0.3/+0.1 | 4.8 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 1/16 | 3/16 | 3 |

| STB-28A | 1.6 | +0.3/+0.1 | 6.4 | +0.4/10.2 | 25.4 | +0.6/+0.2 | 5/64 | 1/4 | 1 |

| STB-28B | 1.6 | +0.3/+0.1 | 6.4 | +0.4/+0.2 | 31.8 | +0.6/+0.2 | 3/32 | 1/4 | 11/4 |

| STB-28D | 1.6 | +0.3/+0.1 | 6.4 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 3/32 | 1/4 | 3 |

| STB-14 | 2 | +0.3/+0.1 | 3.2 | +0.4/+0.2 | 28.6 | +0.6/+0.2 | 3/32 | 1/8 | 11/8 |

| STB-34 | 2.4 | +0.3/+0.1 | 3.2 | +0.4/+0.2 | 127.0 | +0.6/+0.2 | 3/32 | 1/8 | 5 |

| STB-36 | 2.4 | +0.3/+0.1 | 4.8 | +0.4/+0.2 | 28.6 | +0.6/+0.2 | 3/32 | 3/16 | 11/8 |

| STB-36A | 2.4 | +0.3/+0.1 | 4.8 | +0.4/+0.2 | 31.8 | +0.6/+0.2 | 3/32 | 3/16 | 11/4 |

| STB-38A | 2.4 | +0.3/+0.1 | 6.4 | +0.4/+0.2 | 25.4 | +0.6/+0.2 | 3/32 | 1/4 | 1 |

| STB-38B | 2.4 | +0.3/+0.1 | 6.4 | +0.4/+0.2 | 38.1 | +0.6/+0.2 | 3/32 | 1/4 | 11/4 |

| STB-38D | 2.4 | +0.3/+0.1 | 6.4 | +0.4/+.2 | 127.0 | +0.6/+0.2 | 3/32 | 1/4 | 5 |

| STB-310A | 2.4 | +0.3/+0.1 | 7.9 | +0.4/+0.2 | 50.8 | +0.6/+0.2 | 3/32 | 5/16 | 2 |

| STB-310B | 2.4 | +0.3/+0.1 | 7.9 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 3/32 | 5/16 | 3 |

| STB-310C | 2.4 | +0.3/+0.1 | 7.9 | +0.4/+0.2 | 127.0 | +0.6/+0.2 | 3/32 | 5/16 | 5 |

| STB-312 | 2.4 | +0.3/+0.1 | 9.5 | +0.4/+0.2 | 127.0 | +0.6/+0.2 | 3/32 | 3/8 | 5 |

| STB-46 | 3.2 | +0.3/+0.1 | 4.8 | +0.4/+0.2 | 15.4 | +0.6/+0.2 | 1/8 | 3/16 | 6 |

| STB-48A | 3.2 | +0.3/+0.1 | 6.4 | +0.4/+0.2 | 25.4 | +0.6/+0.2 | 1/8 | 1/4 | 1 |

| STB-48B | 3.2 | +0.3/+0.1 | 6.4 | +0.4/+0.2 | 31.8 | +0.6/+0.2 | 1/8 | 1/4 | 11/4 |

| STB-48C | 3.2 | +0.3/+0.1 | 6.4 | +0.4/+0.2 | 57.2 | +0.6/+0.2 | 1/8 | 1/4 | 22/4 |

| STB-48D | 3.2 | +0.3/+0.1 | 6.4 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 1/8 | 1/4 | 3 |

| STB-48E | 3.2 | +0.3/+0.1 | 6.4 | -0.4/+0.2 | 152.4 | +0.6/+0.2 | 1/8 | 1/4 | 6 |

| STB-410 | 3.2 | +0.3/+0.1 | 7.9 | +0.4/+0.2 | 15.2.4 | +0.6/+0.2 | 1/8 | 5/16 | 6 |

| STB-410A | 3.2 | +0.3/+0.1 | 7.9 | +0.4/+0.2 | 38.1 | +0.6/+0.2 | 1/8 | 5/16 | 1 1/2 |

| STB-410B | 3.2 | +0.3/+0.1 | 7.9 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 1/8 | 5/16 | 3 |

| STB-412A | 3.2 | +0.3/+0.1 | 9.5 | +0.4/+0.2 | 50.8 | +0.6/+0.2 | 1/8 | 3/8 | 2 |

| STB-412B | 3.2 | +0.3/+0.1 | 9.5 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 1/8 | 3/8 | 3 |

| STB-412C | 3.2 | +0.3/+0.1 | 9.5 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 1/8 | 3/8 | 6 |

| STB-412D | 3.2 | +0.3/+0.1 | 9.5 | +0.4/+0.2 | 25.4 | +0.6/+0.2 | 1/8 | 3/8 | 1 |

| STB-416 | 3.2 | +0.3/+0.1 | 12.7 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 1/8 | 1/2 | 6 |

| STB-416A | 3.2 | +0.3/+0.1 | 12.7 | +0.4/+0.2 | 25 | +0.6/+0.2 | 1/8 | 1/2 | 1 |

| STB-416B | 3.2 | +0.3/+0.1 | 12.7 | +0.4/+0.2 | 38.1 | +0.6/+0.2 | 1/8 | 1/2 | 1 1/2 |

| STB-416C | 3.2 | +0.3/+0.1 | 12.7 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 1/8 | 1/2 | 3 |

| STB-68 | 4.8 | +0.3/+0.1 | 6.4 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 3/16 | 1/4 | 6 |

| STB-68A | 4.8 | +0.3/+0.1 | 6.4 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 3/16 | 1/4 | 3 |

| STB-610 | 4.8 | +0.3/+0.1 | 7.9 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 3/16 | 5/16 | 6 |

| STB-610A | 4.8 | +0.3/+0.1 | 7.9 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 3/16 | 5/16 | 3 |

| STB-612 | 4.8 | +0.3/+0.1 | 9.5 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 3/16 | 3/8 | 6 |

| STB-612A | 4.8 | +0.3/+0.1 | 9.5 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 3/16 | 3/8 | 3 |

| STB-616 | 4.8 | +0.3/+0.1 | 12.7 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 3/16 | 1/2 | 6 |

| STB-616A | 4.8 | +0.3/+0.1 | 12.7 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 3/16 | 1/2 | 3 |

| STB-620 | 4.8 | +0.3/+0.1 | 15.9 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 3/16 | 5/8 | 6 |

| STB-620A | 4.8 | +0.3/+0.1 | 15.9 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 3/16 | 5/8 | 3 |

| STB-812 | 6.4 | +0.3/+0.1 | 9.5 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 1/4 | 3/8 | 6 |

| STB-812A | 6.4 | +0.3/+0.1 | 9.5 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 1/4 | 3/8 | 3 |

| STB-816 | 6.4 | +0.3/+0.1 | 12.7 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 1/4 | 1/2 | 6 |

| STB-816A | 6.4 | +0.3/+0.1 | 12.7 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 1/4 | 1/2 | 3 |

| STB-820 | 6.4 | +0.3/+0.1 | 15.9 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 1/4 | 5/8 | 6 |

| STB-820A | 6.4 | +0.3/+0.1 | 15.9 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 1/4 | 5/8 | 3 |

| STB-824 | 6.4 | +0.3/+0.1 | 9.1 | +0.4/+0.2 | 152.4 | +0.6/+0.2 | 1/4 | 3/4 | 6 |

| STB-824A | 6.4 | +0.3/+0.1 | 9.1 | +0.4/+0.2 | 76.2 | +0.6/+0.2 | 1/4 | 3/4 | 3 |