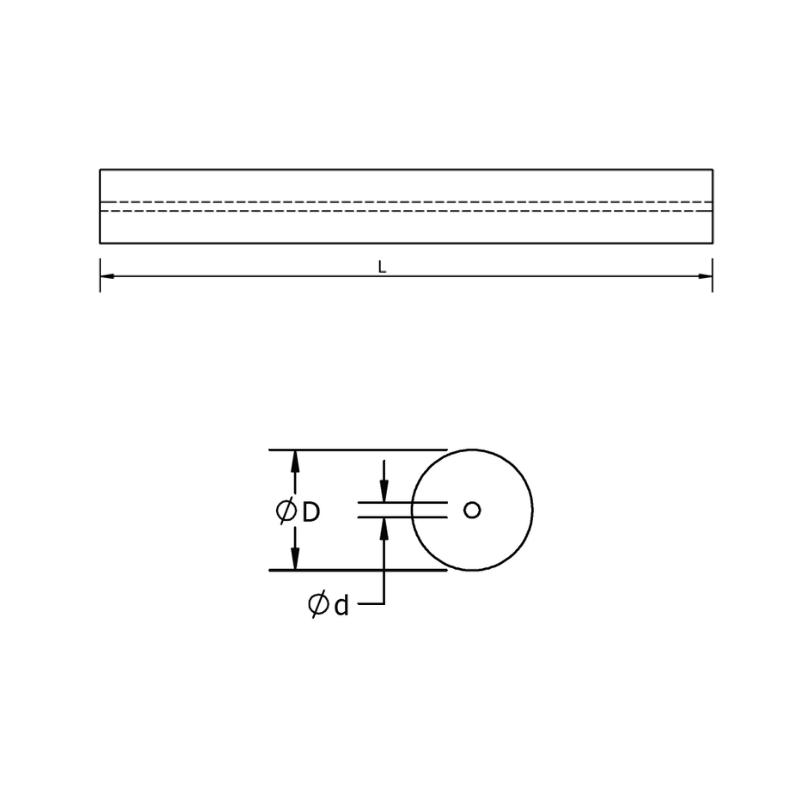

single hole tungsten carbide rod

Our precision-engineered single hole tungsten carbide rods are the ideal solution for a wide range of cutting and wear applications. The central coolant hole enhances performance and extends tool life, making these rods a versatile and cost-effective choice.

- Exceptional Hardness and Wear Resistance: Manufactured from high-quality tungsten carbide for superior durability and longevity.

- Enhanced Cooling and Lubrication: The single, straight coolant hole delivers a targeted flow of coolant directly to the cutting edge, effectively dissipating heat.

- Efficient Chip Evacuation: The coolant flow assists in clearing chips from the cutting zone, preventing tool breakage and improving workpiece finish.

- High Precision and Tight Tolerances: Ground to precise dimensional accuracy (h5, h6, h7) for consistent and reliable performance.

- Versatile Applications: Ideal for the manufacturing of drills, end mills, reamers, and other high-performance cutting tools.

Our single hole tungsten carbide rods are premium-grade tooling components designed for demanding industrial applications. Crafted from a composite of tungsten carbide particles and a metallic binder, typically cobalt, these rods offer an exceptional combination of hardness, wear resistance, and toughness. The defining feature of these rods is the single, precision-drilled hole that runs through the center, providing a direct channel for coolant or lubricant to the cutting edge.

This internal coolant supply is critical in high-speed and high-temperature machining operations. By delivering a focused stream of coolant, our single hole rods significantly reduce thermal stress on the tool, preventing premature wear and extending its operational life. This efficient cooling also allows for higher cutting speeds and feeds, boosting productivity. Furthermore, the constant flow of coolant aids in the evacuation of chips from the cutting area, which is crucial for preventing chip jamming and ensuring a superior surface finish on the workpiece.

Available in a variety of grades (such as K10, K20, K40) and diameters, our single hole tungsten carbide rods are suitable for a broad spectrum of applications. They serve as the foundational material for manufacturing a wide array of cutting tools, including:

- High-performance drills

- End mills

- Reamers

- Engraving tools

- Various wear-resistant parts

Whether you are machining hardened steels, non-ferrous metals, or abrasive composite materials, our single hole tungsten carbide rods provide the reliability and performance necessary to meet the stringent demands of modern manufacturing. Their superior material properties and thoughtful design make them an indispensable component for any precision machining operation.

| Blank-D | Internal Diameter-d | Grinding-D | Length-L | |

|---|---|---|---|---|

| External Diameter(mm) | Tolerance(mm)(+1.5mm) | Internal Diameter-d(mm) | h6(mm) | Tolerance(mm)(+1.5mm) |

| 2.2 | +0.2 . | 0.2-2.0 | 2.0 | 330 |

| 3.2 | +0.2 | 3.0 | 330 | |

| 4.2 | +0.2 | 4.0 | 330 | |

| 5.2 | +0.2 | 5.0 | 330 | |

| 6.2 | +0.2 | 6.0 | 330 | |

| 7.2 | +0.2 | 0.2-3.0 | 7.0 | 330 |

| 8.2 | +0.3 | 8.0 | 330 | |

| 9.2 | +0.3 | 9.0 | 330 | |

| 10.2 | +0.3 | 0.2-4.0 | 10.0 | 330 |

| 11.2 | +0.3 | 11.0 | 330 | |

| 12.2 | +0.3 | 12.0 | 330 | |

| 13.2 | +0.3 | 0.4-6.0 | 13.0 | 330 |

| 14.2 | +0.3 | 14.0 | 330 | |

| 15.2 | +0.3 | 15.0 | 330 | |

| 16.2 | +0.4 | 16.0 | 330 | |

| 17.2 | +0.4 | 0.5-7.0 | 17.0 | 330 |

| 18.2 | +0.4 | 18.0 | 330 | |

| 19.2 | +0.4 | 19.0 | 330 | |

| 20.2 | +0.5 | 20.0 | 330 | |

| 21.2 | +0.5 | 21.0 | 330 | |

| 22.2 | +0.5 | 22.0 | 330 | |

| 23.2 | +0.5 | 0.8-9.5 | 23.0 | 330 |

| 24.2 | +0.5 | 24.0 | 330 | |

| 25.2 | +0.5 | 25.0 | 330 | |

| 26.2 | +0.5 | 26.0 | 330 | |

| 27.2 | +0.5 | 27.0 | 330 | |

| 28.2 | +0.5 | 28.0 | 330 | |

| 29.2 | +0.5 | 29.0 | 330 | |

| 30.2 | +0.5 | 30.0 | 330 | |

| 31.2 | +0.5 | 31.0 | 330 | |

| 32.2 | +0.5 | 32.0 | 330 | |