Introduction

Milling is a cornerstone of metalworking, enabling the creation of precise components across industries such as aerospace, automotive, and mold manufacturing. This article compares four prevalent milling techniques—face milling, shoulder milling, profile milling, and fast feed milling—focusing on their characteristics, applications, machining parameters, and suitable tooling. By exploring specific parameters and market-available tools, this guide aims to assist professionals in selecting the optimal milling strategy for their needs.

Face Milling

Definition and Principles

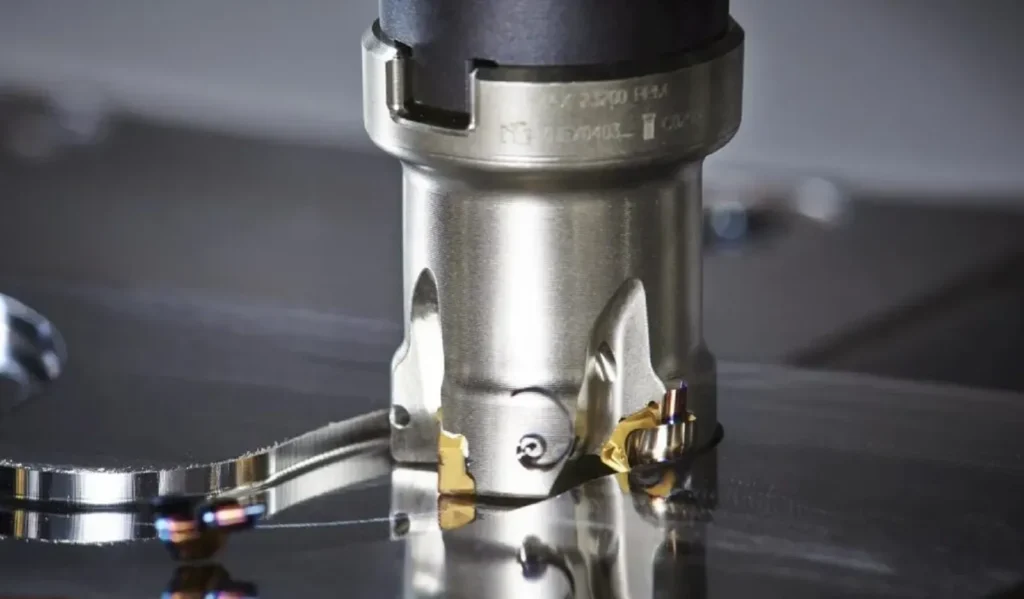

Face milling involves using a multi-tooth face mill to create flat surfaces, with the cutter’s rotational axis perpendicular to the workpiece. It excels in producing large, smooth surfaces with high efficiency.

Technical Characteristics

- Cutting Direction: Perpendicular to the workpiece surface, with cutting forces primarily along the Z-axis.

- Machining Efficiency: High material removal rate (MRR) due to large-diameter, multi-tooth cutters.

- Surface Quality: Achieves low surface roughness (Ra 0.8–3.2 μm), ideal for semi-finishing and finishing.

- Tool Types: Large-diameter face mills with milling inserts.

Typical Machining Parameters

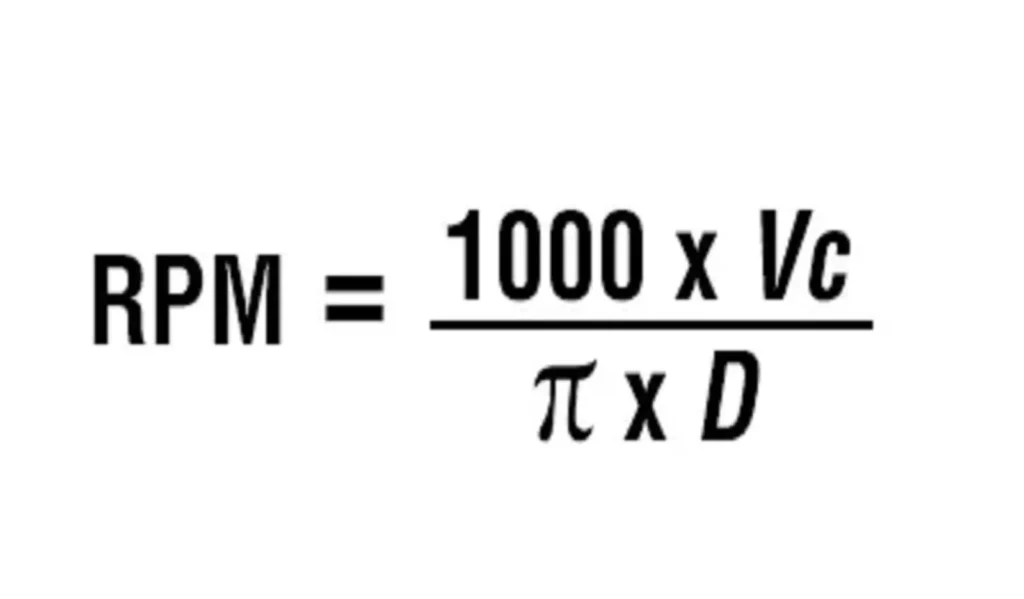

| Material | Cutting Speed (Vc, m/min) | Feed per Tooth (fz, mm/z) | Depth of Cut (ap, mm) | Spindle Speed (n, rpm) |

|---|---|---|---|---|

| Aluminum | 300–600 | 0.1–0.3 | 2–6 | 2000–5000 |

| Carbon Steel | 150–250 | 0.08–0.2 | 2–5 | 1000–3000 |

| Stainless Steel | 80–150 | 0.06–0.15 | 1.5–4 | 800–2000 |

Note: Parameters assume a 50mm diameter cutter with 4–6 teeth, wet cutting conditions.

Common Tools

- Indexable Inserts:

- Sandvik Coromant: R245-12T3 (45° lead angle, versatile for steel and cast iron).

- Kennametal: SEKN1203AFTN (square insert, robust for stainless steel).

- MAPAL: SPKN1204EDR (with wiper edge, excellent surface finish for aluminum).

- Solid Carbide/Solid Tools:

- Kennametal: KSSM 45° Face Mill (supports APKT1604 inserts, ideal for roughing).

- Tormach: 38mm Shell Mill (economical, suitable for steel and aluminum).

- Tool Features: Multi-tooth design for even cutting forces, supports high feed rates (fz 0.08–0.3 mm/z).

Applications

- Surface flattening of castings and forgings (e.g., machine tool beds).

- Large planar surfaces in wind turbine bases or ship components.

- Parts requiring high flatness and surface finish.

Advantages and Disadvantages

- Advantages: High efficiency, excellent surface quality, suitable for high-volume production.

- Disadvantages: Limited adaptability for complex geometries.

Shoulder Milling

Definition and Principles

Shoulder milling uses end mills or side-and-face cutters to machine vertical walls and horizontal bases, forming right-angle or near-right-angle features with high precision.

Technical Characteristics

- Cutting Direction: Multi-axial (X, Y, Z), suitable for right-angle geometries.

- Machining Precision: Tight tolerances (±0.01 mm) for right-angle features.

- Tool Rigidity Requirements: High due to significant cutting forces.

- Tool Types: Square-shoulder end mills or indexable milling cutters.

Typical Machining Parameters

| Material | Cutting Speed (Vc, m/min) | Feed per Tooth (fz, mm/z) | Depth of Cut (ap, mm) | Width of Cut (ae, mm) |

|---|---|---|---|---|

| Aluminum | 200–400 | 0.08–0.2 | 5–10 | 0.5–2 |

| Carbon Steel | 100–200 | 0.06–0.15 | 3–8 | 0.3–1.5 |

| Tool Steel | 80–120 | 0.05–0.1 | 2–6 | 0.2–1 |

Note: Parameters assume a 20mm diameter cutter with 4 teeth, dry or minimum quantity lubrication (MQL).

Common Tools

- Indexable Inserts:

- Sandvik Coromant: R390-11T308 (90° lead angle, ideal for steel and stainless steel).

- Kennametal: APKT11T308 (versatile for aluminum and steel).

- Ingersoll: LNMT110408 (high strength for tool steel).

- Solid Carbide End Mills:

- Kennametal: HARVI I TE (4–6 flutes, high-performance for stainless steel and titanium).

- MAPAL: OptiMill-Shoulder (3–5 flutes, suitable for steel and cast iron).

- Tool Features: 90° cutting angle, small width of cut (ae 0.2–2 mm), robust for high-precision features.

Applications

- Mold cavities with right-angle features.

- Slots, steps, or sidewalls in mechanical components.

- Gearbox housings requiring precise right-angle structures.

Advantages and Disadvantages

- Advantages: High precision, suitable for complex right-angle geometries.

- Disadvantages: High cutting forces, faster tool wear, moderate efficiency.

Profile Milling

Definition and Principles

Profile milling machines along the outer or inner contours of a workpiece, ideal for complex 3D surfaces or profiles. It relies on CNC programming for precise tool paths.

Technical Characteristics

- Cutting Path: Complex, requiring CAM software for accurate CNC programs.

- Machining Precision: High geometric accuracy (±0.005 mm), suitable for intricate surfaces.

- Machining Efficiency: Lower due to complex paths, ideal for low-volume production.

- Tool Types: Ball nose or radius end mills, indexable round inserts.

Typical Machining Parameters

| Material | Cutting Speed (Vc, m/min) | Feed per Tooth (fz, mm/z) | Depth of Cut (ap, mm) | Stepover (ae, mm) |

|---|---|---|---|---|

| Aluminum | 150–300 | 0.05–0.15 | 0.5–2 | 0.1–0.5 |

| Titanium | 40–80 | 0.03–0.08 | 0.3–1 | 0.05–0.2 |

| Stainless Steel | 60–120 | 0.04–0.1 | 0.4–1.5 | 0.08–0.3 |

Note: Parameters assume a 10mm ball nose cutter with 2–4 flutes, wet cutting, high-precision CNC.

Common Tools

- Indexable Inserts:

- Sandvik Coromant: RCMT10T3MO (round insert, suitable for roughing curved surfaces).

- Kennametal: RDMT1204MO (versatile for steel and titanium).

- MAPAL: RDMX1003 (high precision for aerospace materials).

- Solid Carbide End Mills:

- Kennametal: HARVI III Ball Nose (2–4 flutes, ideal for titanium and composites).

- Sandvik Coromant: CoroMill Plura Ball Nose (high precision for mold surfaces).

- Tool Features: Round or ball-shaped cutting edges reduce cutting forces, suitable for multi-axis machining.

Applications

- Aerospace components (e.g., turbine blades).

- Complex mold cavities and curved surfaces.

- Medical implants (e.g., orthopedic components).

Advantages and Disadvantages

- Advantages: High flexibility for complex 3D shapes, excellent precision.

- Disadvantages: Complex programming, lower efficiency, high tool and machine requirements.

Fast Feed Milling

Definition and Principles

Fast feed milling (also known as high-feed milling) uses high feed rates and shallow depths of cut to maximize material removal, ideal for roughing hard materials.

Technical Characteristics

- Cutting Parameters: High feed rates (Vf 4000–12000 mm/min), shallow depths (ap <1 mm).

- Machining Efficiency: Extremely high MRR (>100 cm³/min), suitable for high-volume roughing.

- Tool Life: Extended due to low cutting forces and optimized heat distribution.

- Tool Types: Dedicated high-feed milling cutters with specialized insert geometries.

Typical Machining Parameters

| Material | Cutting Speed (Vc, m/min) | Feed per Tooth (fz, mm/z) | Depth of Cut (ap, mm) | Feed Rate (Vf, mm/min) |

|---|---|---|---|---|

| Tool Steel | 100–180 | 0.5–1.2 | 0.2–0.8 | 5000–10000 |

| Cast Iron | 150–250 | 0.6–1.5 | 0.3–1 | 6000–12000 |

| Titanium | 50–100 | 0.4–0.8 | 0.2–0.6 | 4000–8000 |

Note: Parameters assume a 25mm diameter cutter with 4 teeth, dry or MQL, high-power spindle.

Common Tools

- Indexable Inserts:

- Sandvik Coromant: HNGX06 (small lead angle, optimized for high feed).

- Kennametal: SDMT1204 (robust for tool steel).

- Ingersoll: HNGJ0905 (low cutting forces for titanium).

- Solid Carbide End Mills:

- Kennametal: Mill 4-11 High Feed (4 flutes, suitable for steel and stainless steel).

- MAPAL: OptiMill-HighFeed (3–5 flutes, ideal for hard materials).

- Tool Features: Small lead angles (10–15°), chip-thinning effect, supports high feeds (fz 0.4–1.5 mm/z).

Applications

- Roughing of tool steel or titanium alloys.

- Rapid material removal in automotive molds or aerospace structures.

- High-efficiency roughing prior to finishing operations.

Advantages and Disadvantages

- Advantages: Exceptional efficiency, long tool life, ideal for hard materials.

- Disadvantages: Poor surface quality (Ra 6.3–12.5 μm), requires subsequent finishing.

Comparative Analysis

Technical Parameters

| Technique | Cutting Speed (m/min) | Feed Rate (mm/min) | Depth of Cut (mm) | Tool Life |

|---|---|---|---|---|

| Face Milling | 80–600 | 500–3000 | 1.5–6 | Medium–Long |

| Shoulder Milling | 80–400 | 300–2000 | 2–10 | Medium |

| Profile Milling | 40–300 | 100–1500 | 0.3–2 | Short |

| Fast Feed Milling | 50–250 | 4000–12000 | 0.2–1 | Long |

Machining Efficiency

- Material Removal Rate: Fast feed milling leads (>100 cm³/min), followed by face milling, with shoulder and profile milling lower.

- Processing Time: Fast feed milling is fastest, profile milling slowest.

Surface Quality and Precision

- Surface Roughness: Face milling best (Ra 0.8–3.2 μm), shoulder milling next, profile milling varies, fast feed milling poorest.

- Precision: Profile and shoulder milling highest, face milling moderate, fast feed milling for roughing.

Material and Geometry Suitability

- Materials:

- Face Milling: Aluminum, steel, cast iron.

- Shoulder Milling: Steel, stainless steel, tool steel.

- Profile Milling: Titanium, composites, stainless steel.

- Fast Feed Milling: Tool steel, titanium, cast iron.

- Geometries:

- Face Milling: Large planes.

- Shoulder Milling: Right-angle features, slots.

- Profile Milling: Complex contours, 3D surfaces.

- Fast Feed Milling: Any shape for roughing.

Cost and Equipment Requirements

- Tool Costs: Fast feed inserts are costly but long-lasting, profile milling tools wear quickly, face and shoulder milling moderate.

- Equipment: Profile milling requires high-precision CNC, fast feed milling needs high-power spindles, face and shoulder milling less demanding.

Tool Selection Guide

| Technique | Recommended Inserts | Recommended Solid Tools | Key Parameters | Applications |

|---|---|---|---|---|

| Face Milling | R245-12T3, SEKN1203 | KSSM 45°, 38mm Shell Mill | ap 2–6 mm, fz 0.08–0.3 mm/z | Large planes, castings |

| Shoulder Milling | R390-11T308, APKT11T308 | HARVI I TE, OptiMill-Shoulder | ap 3–10 mm, ae 0.2–2 mm | Right-angle slots, molds |

| Profile Milling | RCMT10T3MO, RDMT1204 | HARVI III Ball Nose, CoroMill Plura | ap 0.3–2 mm, ae 0.05–0.5 mm | Curved surfaces, aerospace parts |

| Fast Feed Milling | HNGX06, SDMT1204 | Mill 4-11, OptiMill-HighFeed | ap 0.2–1 mm, Vf 4000–12000 mm/min | Hard material roughing |

- Inserts: Cost-effective, indexable, ideal for high-volume production, versatile across materials.

- Solid Carbide End Mills: High precision, suited for small diameters or complex geometries, common in finishing.

- Considerations:

- Inspect inserts for wear every 500–1000 minutes of machining.

- Use rigid tool holders for solid end mills to minimize vibration.

- Select coatings based on material (e.g., TiAlN for high-temperature alloys, TiCN for steel).

Practical Selection Guidelines

- Large Planar Surfaces: Use face milling (Vc 150–600 m/min, ap 2–6 mm) with tools like R245-12T3 or KSSM face mills for efficiency and surface quality.

- Right-Angle Features: Opt for shoulder milling (fz 0.05–0.2 mm/z, ap 2–10 mm) with R390-11T308 inserts or HARVI I TE end mills for precision.

- Complex Contours: Choose profile milling (Vc 40–300 m/min, ae 0.05–0.5 mm) with RCMT10T3MO inserts or CoroMill Plura ball nose mills for flexibility.

- High-Efficiency Roughing: Select fast feed milling (Vf 4000–12000 mm/min, ap 0.2–1 mm) with HNGX06 inserts or Mill 4-11 high-feed mills for hard materials.

Case Studies

- Case 1: An automotive mold plant machining large mold planes used face milling (Vc 200 m/min, fz 0.15 mm/z, ap 4 mm) with R245-12T3 inserts, achieving high efficiency and flatness.

- Case 2: An aerospace facility machining turbine blade contours employed profile milling (Vc 60 m/min, fz 0.05 mm/z, ae 0.1 mm) with HARVI III ball nose mills, ensuring high precision.

- Case 3: A tool steel mold roughing operation used fast feed milling (Vf 8000 mm/min, ap 0.5 mm) with HNGX06 inserts, followed by shoulder milling with R390-11T308 for finishing.

Conclusion

Face milling excels in efficiency and surface quality for planar surfaces, shoulder milling offers precision for right-angle features, profile milling provides flexibility for complex contours, and fast feed milling maximizes roughing efficiency. Tool selection—whether indexable inserts (e.g., R245-12T3, HNGX06) or solid carbide end mills (e.g., HARVI III, Mill 4-11)—must align with material, geometry, and machine capabilities. Optimizing machining parameters enhances performance and cost-effectiveness. As intelligent and hybrid machining technologies advance, these milling techniques will continue to evolve, meeting demands for higher precision and productivity.

References

- Sandvik Coromant. (2023). Milling Technology Handbook.

- Kennametal. (2023). Solid Carbide End Milling Catalog.

- MAPAL. (2023). NeoMill Milling Program.

- ISO 13399: Cutting Tool Data Representation and Exchange.

- Sandvik Coromant Milling Knowledge