HNMX داخل کریں۔

As a leading supplier of cutting-edge milling solutions, we offer a comprehensive range of BDMT inserts designed for maximum efficiency and durability in large-scale industrial applications. Our products cater to wholesale customers seeking top-quality milling tools for their operations.

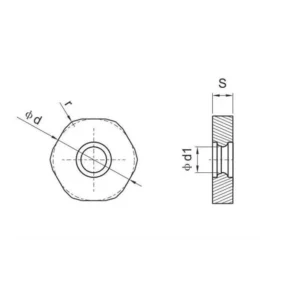

HNMX Insert Specification Guide

- H: This typically refers to the shape of the insert. In this case, ‘H’ usually stands for “Hexagonal” shape.

- N: Often indicates a specific angle or clearance feature of the insert.

- M: Commonly stands for “Medium,” which could refer to the feed rate, chip breaker design, or other cutting characteristics.

- X: This might denote a particular feature, tolerance class, or could be a manufacturer-specific designation.

HNMX Insert Cutter Compatibility

- Milling inserts are replaceable bits that are used to machine tough some of the toughest materials.

- Some of the materials that they shape or cut are steel, stainless steel, cast iron, non-ferrous materials, Titanium, hardened steel, and plastic.

- The ONMY Milling Insert is a high-quality insert designed to sharpen the cutting edges on face mills.

- Carbide construction offers excellent material removal rates in both hard and soft materials.

- It is also capable of removing excess material more quickly than traditional cutters.

- The material of the ONMY milling insert HNMX is carbide.

- ONMY Milling Inserts are designed for milling in steel and stainless steel.

- ONMY Milling Inserts are designed to reduce cutting forces and extend the life of the insert.

ایپلی کیشنز

Inserts excel in various industrial milling operations:

- General face milling

- کندھے کی گھسائی کرنے والی

- Roughing and finishing operations

- Suitable for materials including steel, stainless steel, and cast iron

HNMX inserts are generally used for heavy-duty milling operations. The hexagonal shape provides multiple cutting edges, allowing for longer use before replacement is necessary. These inserts are often favored for their stability and ability to handle high cutting forces.

These inserts are typically used in face milling, shoulder milling, and other similar operations, especially when working with tough materials or in situations requiring high material removal rates.

Why Choose Our Inserts?

Superior Durability

Our HNMX inserts are manufactured using premium-grade carbide materials, ensuring exceptional wear resistance and longer tool life, even under demanding cutting conditions.

Versatile Performance

Designed to excel in both roughing and semi-finishing operations, our HNMX inserts reduce the need for frequent tool changes, enhancing overall productivity.

Cost-Effective Solution

With six cutting edges per insert, our HNMX design offers excellent value for money, reducing your tooling costs over time.

Easy Indexing

Compatible with standard tool holders, our inserts allow for quick and simple indexing, minimizing downtime.

Our Production Capability